Goldacres have continually led the way delivering self-propelled sprayers that are suited to Australian farming, our philosophy has always been to produce quality sprayers, built to provide the best possible efficiency for the most cost-effective, accurate spraying tasks.

Over 20 years of self-propelled manufacturing has shown operators there is a need for lightweight, high clearance, high capacity sprayers. Our G6 Crop Cruiser is the best possible solution for large scale dryland farming enterprises.

Faster, smarter, stronger – the G6 has raised the bar in terms of operator comfort and usability. Under its bodywork lurks a totally new sprayer, bringing features to the market that make spraying easier, quicker and more enjoyable than ever before.

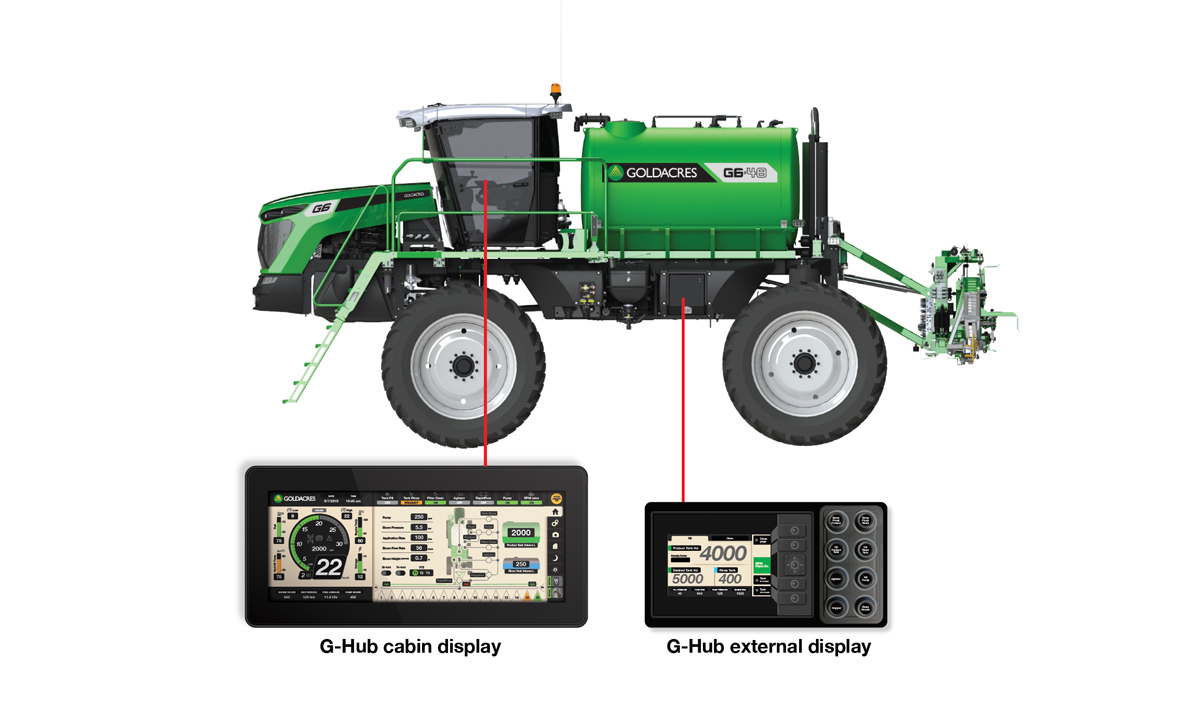

Our latest model features the G-Hub – Goldacres integrated system, an intuitive and easy to use electronic control system, the all-new Tritech RivX boom for unmatched boom stability along with a host of new features for improved sprayer performance and reliability.

The best sprayer in the business deserves the best cabin in its class – Welcome to business class.

The sprayer is one of the most utilised items of equipment on the farm today. Long hours day after day places plenty of demand on the operator to get the spraying program completed. At times it’s like a second office, where mobile communication means your sprayer becomes your place of business.

The Crop Cruiser cabin makes it all possible, with features like the very latest in European styling and finishes. Narrow profile four post frame with external truss Roll Over Protective Structure (ROPS), double skinned rear wall and extensive sound deadening provide a strong, yet peaceful uninterrupted view of the job at hand.

Centrally located cabin with suspension and air ride seat help reduce operator fatigue, allowing more hectares to be completed in a day. Putting it simply, you have the best laid out controls. Read on and find out why the Goldacres Crop Cruiser cabin really is “business class”

Imagine having an operator side console where without lifting your arm or moving your eyes you can easily operate and view all vital sprayer functions – Imagine no more.

- Adjustable mounting of sprayer G-Hub console is in line of sight, but low enough so it does not hinder the outside view.

- Push button transmission selector. Displays selected and actual gear.

- G-Motion™ handle. Adjustable position caters for all operators.

- Boom folding functions.

- Various machine functions like spray pump on/off, 4WD (if optioned) and boom recirculation just to name a few.

- Hinged padded armrest which reveals a large storage area.

Intuitive & easy to use system with on-board diagnostics

The G-Hub system comprises of a cabin display, external display, PLC (programmable logic controller), I/O modules, sensors and switches to control and monitor all critical machine functions and packages it all into one easy to use fully integrated system. The G-Hub also operates seamlessly with all leading steering and mapping providers using the ISO BUS protocol. On-board diagnostics allows operators to quickly pinpoint problems without the need for laptops, specialised service tools or internet connections, thus minimising downtime.

G-Hub – Cabin display

Using a low profile 12” full colour touch display nicely situated into the operator side console without restricting external vision. The display is segmented into two screens. 1. Drive train information and 2. Sprayer Information.

G-Hub – External display

Featuring a full colour 5” screen and button panel to control all fill and clean functions with the push of a button.

Comfortable, adjustable and intuitive.

The new G-Motion™ handle literally puts the sprayer control into the palm of your hand. Functions such as: Individual boom wing tilt, dual boom wing tilt, main boom lift/lower, fence line L/R, auto steer cancel/resume, cruise control set/resume and increase/decrease, master spray on/off mean all spraying operations can be done without moving your hand from the G-Motion™ handle.

- Cruise Set / Increase

- Cruise Resume / Decrease

- Cruise Cancel

- Boom Master On / Off

- Tilt Right Up / Tilt Left up / Tilt Right Down / Tilt Left Down

- Boom Lift / Left Fence Nozzle / Right Fence Nozzle / Boom Lower

- GPS Auto Steer

- Dual Tilt Up (Behind)

- Dual Tilt Down (Behind)

Cruise Control

Three modes of operation. Classic, variable and 2 speed.

- Classic cruise control is our traditional system where the operator simply drives to the desired speed and presses the set button. The cruise speed can be cancelled and resumed at any time. Goldacres, Allison and Cummins have worked extensively together to improve the stability of the system in varying ground conditions to reduce hunting and improve speed stability.

- Variable cruise is a new mode where the operator can set a spray speed (High) and a headland speed (Low). The joystick is then either pushed forward or pulled back to infinitely vary the speed in between these two settings.

- 2 speed mode works very similar to the variable except the sprayer is either operating at the low or high speed, there is no infinite speed setting in between.

In today’s fast-changing precision farming landscape it is easy to be left behind in the technology stakes.

That’s why Goldacres make it easy, with multiple solutions from the basic requirements to the top end needs.

For more than 2 decades Goldacres have relied on Raven to provide complete flow control systems with matched components to give, quite simply, unmatched flow control accuracy and stability.

At the heart of the control system is a positive displacement pump which runs at a consistent rpm. This creates known flow rates across varying pressures, essential for accurate and stable flow control. In addition, two system-critical components, a flow meter and three-way regulator valve combine to help achieve fast “on target rate”, plus greater flow stability with known tank agitation.

ISOBUS systems

Sprayer cabins can get pretty busy with the vast range of systems requiring individual control consoles. The ISO BUS standard brings all the systems together into the one display, called a virtual terminal (VT). Essentially each system contains the brains, while the VT is simply the interface between the two. This means only one operator console is required. Goldacres offer the option for ISO BUS compatibility, allowing numerous leading VT displays to take over the sprayer control duties. Features like 3TS, pump speed readout, ultrasonic boom levelling plus sprayer steering and task control applications can all be monitored by the one display.

Raven RCM

The G6 Crop Cruiser is fitted with the Raven Control Module (RCM). The RCM features dual nodes which enable 2 screens to be used simultaneously, 16 boom section control, remote diagnostics via Bluetooth and 3TS Pro compatibility.

Multiple suspension systems along with cabin position on the chassis give the operator a smooth comfortable ride

A cabin positioned behind the front axle gives a naturally superior ride due to the reduced vertical movement. In addition, the suspended cabin, air seat and five-link airbag chassis suspension system give the operator a smooth, comfortable ride.

- Air ride suspension seat

- Suspended cabin

- Five-link suspension with torque rods, rear anti-sway bar with airbags on all four corners

- TriTech RivX boom suspension controlling pitch, roll and yaw

We know that one size does not fit all

Seven-way adjustable seat, adjustable side console, adjustable G-Motion™ handle position and adjustable steering column ensure operators of all sizes can find a place to do their best work.

Two’s not a crowd

When the days are long and a bit of company is needed it’s nice to have a proper place for someone to sit. The padded training seat with seatbelt is large and comfortable without hindering the operator’s vision or space. The seat also folds away to reveal a large storage area with optional cooling module for food and beverages.

Keep your cool

The Australian summers can be long and hot, but that doesn’t mean you should be. The fully integrated automatic climate controlled air conditioning system with carbon filter allows the operator to set and forget. Strategically placed air ducting ensures air movement is even around the cabin. There’s even an overhead cooled storage compartment for a drink bottle.

The high mounted, centrally positioned cabin gives the operator a bird’s eye view of all corners of the sprayer.

From the driver’s seat, the operator has an impressive 320-degree view of the surroundings. All 4 wheels can be seen (rear wheels via rear view mirrors) which aids in row crop work, and maneuvering around safely. Looking over your shoulder the operator can see an impressive 89% of the boom width*.

The main access platform features longitudinal slots to see through. Curved glass on all four sides with strategically

placed narrow profile 4 post-ROPS frame. From the driver’s seat looking forward the narrow bonnet with integrated row alignment contour assists the operator to line the sprayer within the row. Vision of the front wheels aid alignment. The hydraulic oil reservoir with level and temperature gauge, backlit spray and boom hydraulic pressure gauges are clearly visible.

The Goldacres Crop Cruiser has set the benchmark in terms of driving dynamics for many years.

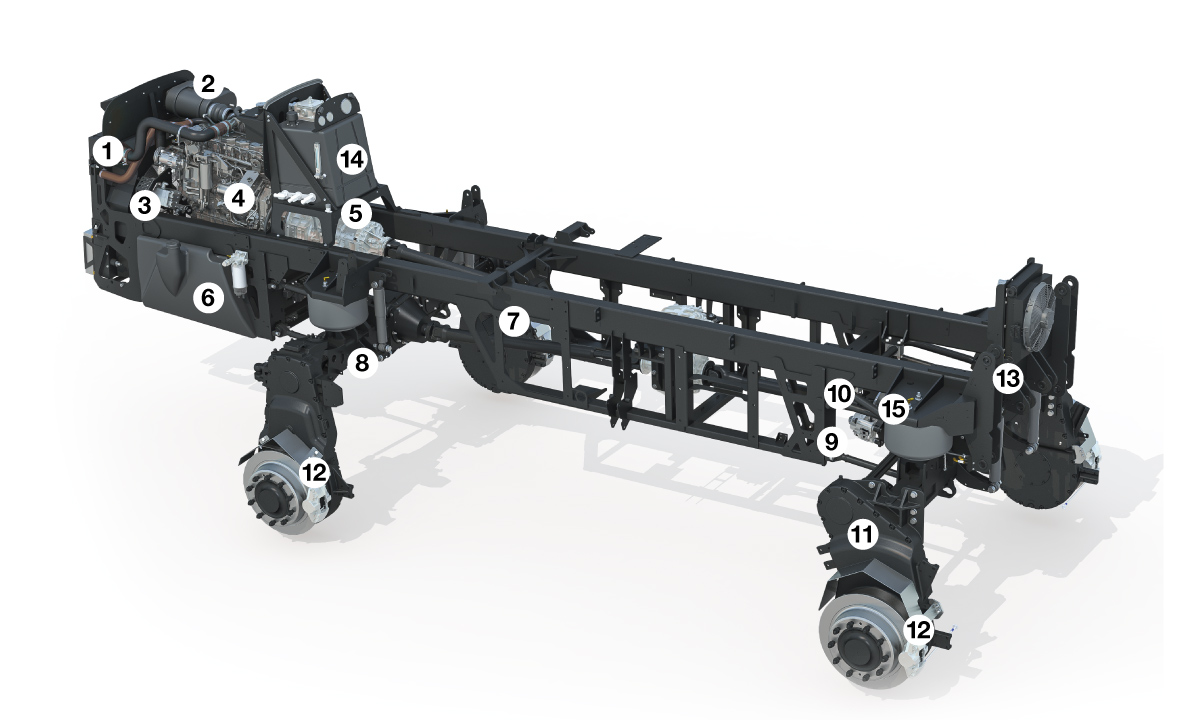

The secret to this is the rigid chassis, suspension and mechanical driveline system which provides the foundation to build on. The main chassis is a fully welded, torsionally rigid semi truss structure. This offers not only the best sprayer and boom ride but also the optimum balance between strength and weight.

The proven 5 link suspension featuring polyurethane bushed heavy-duty torque rods, rear anti-sway bar and air springs on all four corners provide a stable, yet smooth ride. All this combined with the full mechanical driveline results in performance on the ground.

- Large vertically stacked cooling system for fuel, transmission, water jacket, charge air and air conditioning. Optimised cooling fan to reduce noise whilst still provide maximum airflow.

- Over The Radiator (OTR) air cleaner system with twin stage filtration provides cool clean air to the engine.

- Variable speed cooling fan for reduced fan noise, improved fuel economy and increased power.

- Cummins Tier 3 QSB 6.7L – 6-cylinder engine rated to 168kw (225hp) and 949N.m (700 lb-ft). Featuring 2 stage torque curve for maximum driveline life without compromising performance.

- Allison 2500 series 6-speed transmission with electronic push-button selector. Double overdrive reduces engine RPM whilst still maintaining 50km/hr transport speed. Lock-up clutches improve performance whilst dramatically reducing heat build-up and fuel usage.

- 440L polyethylene fuel tank with both left and right-hand side filling points provides enough fuel for the longest spray days without the need to refuel.

- Trussing of chassis in the centre provides maximum strength with minimum weight. 200 x 100 x 9mm main rails.

- Oversize 110mm hard chromed steering kingpin front leg with mechanical link between front wheels ensures correct steering Ackerman angles & alignment*

- 5 link torque rods with rear sway bar. 4 x rolling lobe air springs with ride-height levelling. Shock absorbers on all corners, front feature double knuckle for extreme axle articulation.

- 48mm anti-sway bar reduces body roll without limiting individual wheel travel.

- Oil filled final drive drop leg puts the power to the ground. Both 2WD and true 4WD versions available.

- 4-wheel disc brakes with full hydraulic brake circuit. Spring operated diff mounted disc park brake.

- Integrated boom connection points. Non-flexing chassis provides a stable platform for boom control.

- 100L hydraulic oil reservoir with level and temperature sensors.

- New limited-slip differential (LSD) provides superior traction to both rear wheels.

*On fixed track width versions only. Adjustable track sprayers feature individual steering cylinders

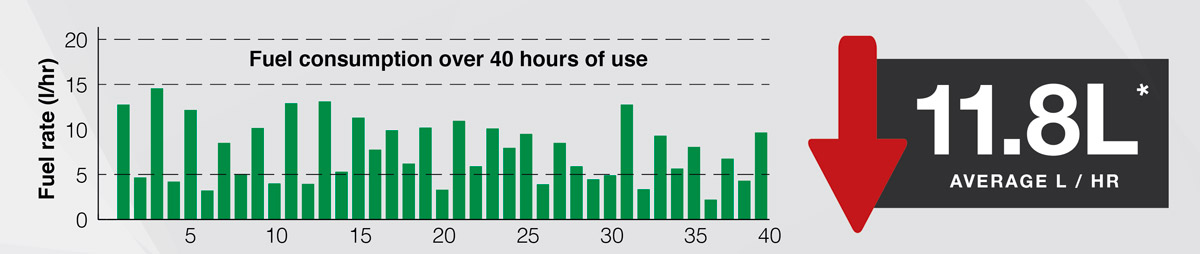

More than ever before has every dollar counted.

Today’s farmer must evaluate capital equipment purchases carefully to ensure that the return on investment is maximised. With all the models and options available today the choice has never been greater, or harder. Look past the sticker price of the initial purchase, dig a little deeper and substantial variations in sprayer design can make all the difference. The operating costs are where so much money can be saved. This is where the Goldacres Crop Cruiser mechanical driveline system sets it apart from its hydrostatic drive competitors.

There are numerous benefits with a mechanical drive sprayer. Less maintenance costs, less noise, significant fuel reduction, less heat generated, lower engine rpm, lower horsepower required, more torque at the wheels, longer component life.

These all equate to substantially lower operating costs. Reports back from owners state that the Goldacres Crop Cruiser can use up to a third of the fuel than some hydrostatic drive sprayers in the same situation. So when the time comes to make that important purchase, dig a little deeper and turn the Goldacres mechanical advantage into your advantage.

*Average RPM and fuel usage is taken from a G6 Crop Cruiser operating in the Western district of Victoria over a 40 hour period.

Tyre size available are:

- 480/80R46

- 480/80R50

- 520/85R46

- A larger diameter tyre provides a larger footprint for less soil compaction and can also carry significantly more weight, meaning tyres can be inflated to lower pressures without damaging the sidewalls.

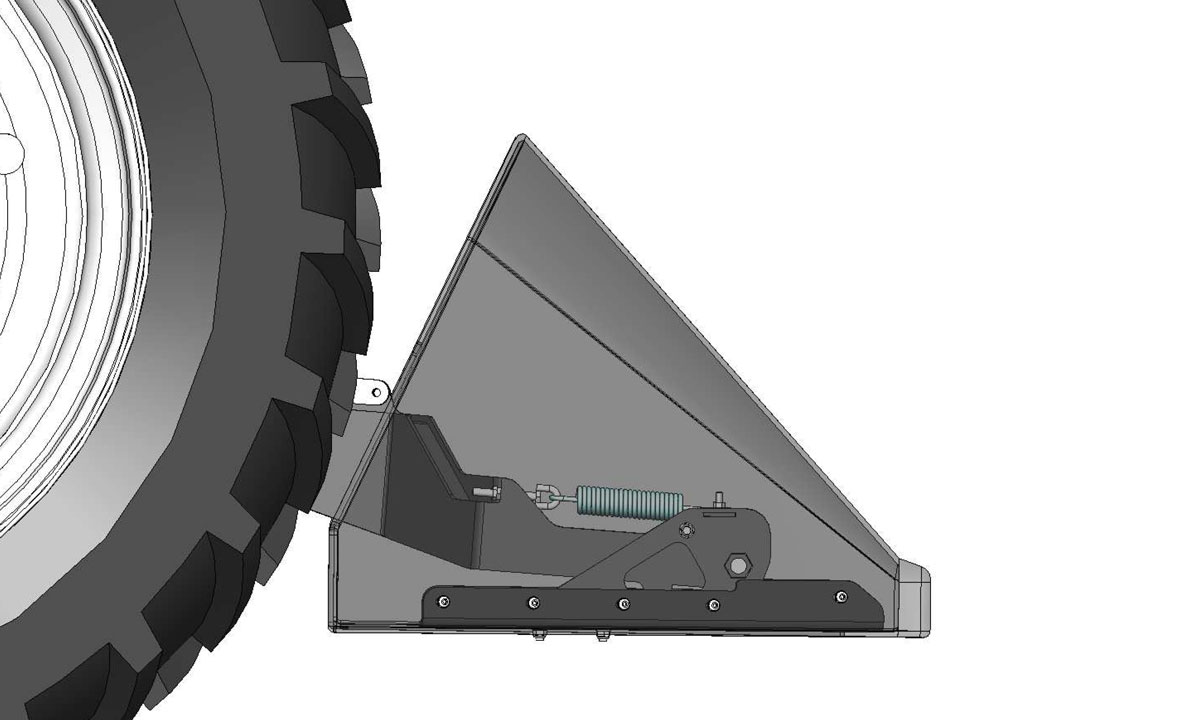

- Crop dividers are now an option for front and rear wheels.

- The nose cone is made from polyethylene for increased impact strength and wearing ability.

- The nose cone features a spring operated swing back feature in case of ground strikes.

- Height is also manually adjustable.

- The dividers will work with all sizes of tyres.

Today’s sprayers are full of bells and whistles which makes spraying a whole lot easier, comfortable and efficient, but it’s easy to forget what the end goal is. Precise chemical application.

Boom control can be the difference between a good spray result, and no result at all. Goldacres understand this and it is why all our sprayer designs are centred around the boom first and foremost.

Why do Goldacres booms ride so well?

Goldacres pioneered the use of lightweight aluminium in the outer boom wings over two decades ago. The philosophy was, and still is today that mass on a boom is fine so long as it is as close to the centre as possible. Reduced mass on the boom extremities reduces boom forces in both yaw and roll. This combined with the unique boom suspension results in a very stable boom ride, regardless of the terrain.

TriTech booms are contour following, meaning that the boom level will be referenced to the sprayer chassis and not purely on gravity such as a pendulum boom. This allows the sprayer to transverse the sides of hills and contours whilst keeping the boom level to the ground at all times. This results in placing the nozzle at the optimum height above the target.

Some manufacturers claim that by placing the boom out the front of the sprayer the job is made easier. But is it really? There are many reasons why rear mounted booms are better.

- The sprayer is always moving away from the chemical spray, meaning the chemical ends up on the target, not on the sprayer.

- Access to the sprayer cabin is at the front, free from chemicals. Front mounted boom sprayers have access at the rear which could have chemical residue due to driving into the spray.

- A boom at the rear allows the sprayer to backup and then spray out of a corner.

- When travelling down the road forward visibility is not hampered by the boom centre section.

- A front mounted boom by its nature must have a relatively clear centre section so the operator can see through when folded. This means the boom suspension system must be quite basic, or non existent, resulting in poor boom performance and ride. A rear mounted boom is not constrained by this and can therefore feature very sophisticated boom suspension systems, which result in superior boom ride.

Strength, Stability, Reliability & Control.

The TriTech boom range is designed for operators who demand the utmost performance, reliability and control. Time and time again the TriTech boom has been named “No.1 for boom stability”* which at the end of the day, results in a superior spray result.

Features such as hydraulic yaw which precisely controls the forwards and backwards movement of the boom wings to minimise the under and over applying of chemical are now standard on all widths.

The strategically placed centre section suspension links help isolate the sprayer chassis movement over rough terrain. Combined with the tuned damping characteristics allows precise roll control enabling an optimal and consistent nozzle height to be maintained, even without the use of electronic height control systems.**

All TriTech booms are constructed using lightweight trussing techniques, which allows for a stronger design without weight, the enemy of boom agility.

The No 1 boom now performs even better. The 36-42m Tritech RivX boom.

Instantly recognisable with a structural riveted outer boom wing, bright yellow boom tips and a hydraulic fold mechanism. The TriTech RivX boom lifts the standard for spray boom construction and performance.

The outer wings are aluminium and feature no welding. Thin mild steel plates are glued and riveted to the aluminium to produce a very strong truss without any heat effected aluminium areas. The boom inner and outer wings are fully symmetrical meaning left and right are interchangeable.

The fold system uses hydraulics and links but, unlike most other booms the hydraulic fold cylinder is fully retracted when the boom is fully open, this is when the hydraulic cylinder is at its strongest position and there is no chance of bending a cylinder rod. In addition to the hydraulic folding, the mechanism includes a hydraulic breakaway system in the event of a collision with an object.

Bi-fold is now a standard feature of this design.

Booms also have an auto fold system which is controlled through the G-Hub system.

Centre section

The boom centre section for the 36 and 42m booms has been lifted directly from the 48m design. The boom is connected to the centre using a high strength lower pivot arm which supports the boom in both torsional and lateral directions. The top of the boom is connected by the tilt cylinder, this connection system provides a strong link between the inner boom and centre section folding mechanism.

Boom inners

The inner boom wings feature a single 100 x 50mm top cord and twin 50 x 50mm lower cords. A key design element of this boom is the symmetrical construction technique. Outer wing fold points have adjustable spherical joints allowing easy boom adjustment. Hydraulic flip-down latches hold the outer wing in place once folded.

Boom outers

The RivX outer boom wings are constructed using a combination of thin gauge mild steel connection plates, high strength industrial steel rivets, adhesives and structural grade aluminium profiles.

Hydraulic wing fold

Hydraulic folding the mechanism includes a hydraulic breakaway system in the event of a collision with an object. This allows adjustable holding force with fully adjustable return speed.

Boom breakaway

The breakaway incorporates a protection frame. The nozzles, lights and fence line nozzle are fully protected by this design. Breakaway section is also fully riveted and allows for a transport width on 36 & 42m booms of under 3500mm.

Boom plumbing

Boom plumbing is 1” for both higher application rates and also improves pressure drop along the length of the boom. The boom lines and nozzle bodies are also mounted below the main structure of the boom and protected by a replaceable protection bar. By placing the nozzles under the main structure any spacing or configuration can be achieved and all nozzles are in perfect alignment.

Auto boom fold

Push boom fold button on the console to raise, auto level and fold-in.

Built with productivity and efficiency in mind

Massive productivity gains available with the fitment of the 48m tri-fold boom.

Wider booms = greater productivity. If we compare a 36m boom to a 48m we can see potentially 33% increase in productivity (depending on application rate)

- 36m boom at 25km/hr = 90ha/hr.

- 48m boom at 25km/hr = 120ha/hr.

- Outer wings feature a unique hydraulic break back and break forward function to help fight the forces of yaw while also providing security in the chance of a boom collision.

- Inner wings feature forward and rearward hydraulic dampening in conjunction with full yaw control.

- While using the boom in the folded 20m position the inner wing features a hydraulic latch to secure the outer and inner wing for increased boom rigidity and longevity.

- Single spray bar puts all spray nozzles in perfect alignment, allowing virtually any nozzle combination or configuration to be mounted on the boom.

- 1” poly tube plumbing for reduced pressure drop resulting in more even nozzle flow rates.

- Boom construction comprises of mild steel inner wings with aluminium used for the middle, outer and breakaway sections. This provides strength and durability where needed and weight savings as required. In fact, this boom is comparable in weight to some other all aluminium booms on the market.

- The boom truss structure is significantly deeper and wider than our other width booms. This reduces cord stresses which improves overall longevity.

Spray widths

Three working spray widths can be achieved;

20m – mid section folded back.

36m – outer section folded back.

48m – all open.

Why is boom ride and stability so important?

A boom which bounces, sways or yaws deposits chemical unevenly on the target. This can result in weed escapes and may even contribute to resistant weeds.

The Goldacres TriTech suspension system has been developed to provide you with the best boom ride possible and assist in an accurate application. Working in conjunction with the chassis airbags three-way suspension that works to reduce boom pitch, roll and yaw – the three enemies of accurate application. A combination of springs and shock absorbers, as well hydraulic cylinders and accumulators all work together to provide the best boom ride possible. The TriTech suspension system has contributed to Goldacres consistently having the best boom ride when measured against

competitor machines.

Yaw

Hydraulic yaw – Two opposing hydraulic cylinders are mechanically connected together either side of the pivoting boom centre section.

As the centre yaws one cylinder is retracted, the other is extended.

This results in oil movement which compresses in a nitrogen charged accumulator. The result is precise boom yaw control.

Roll

Delta links – The key to the superior boom ride is the strategically placed delta links. In all there are four links. Each link features spherical ball ends which allow the centre to move in all directions.

Roll centre point – The roll centre point is the location at which the boom pivots around, both in roll & yaw.

Roll dampeners – Reduces high frequency oscillation of the boom roll.

Boom stability is only part of the chemical application story, optimum droplet sizing, pressure, nozzle flow rate and spray uniformity across the boom width are all critical to accurate chemical application

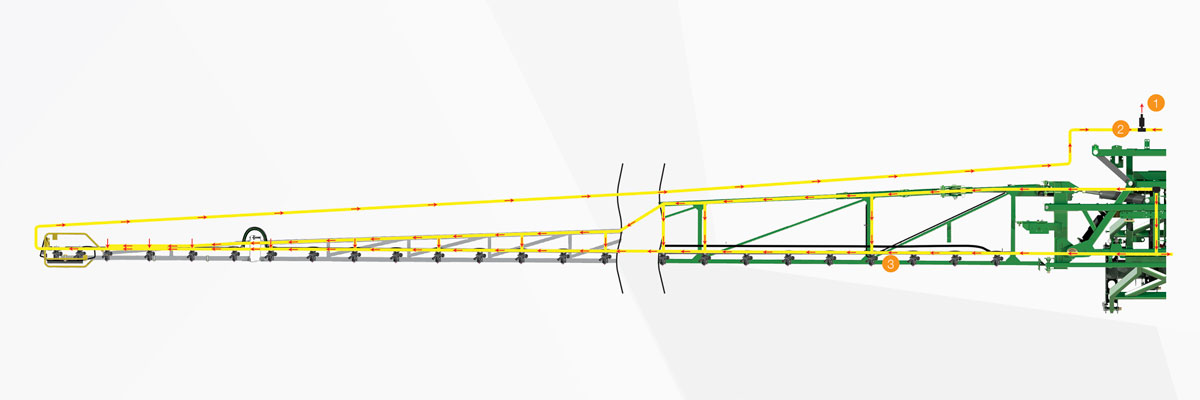

RapidFlow – Boom Recirculation* allows the sprayer boom lines to be fully primed without spraying a single drop. This reduces wastage at the start of a tank load or when switching chemicals. RapidFlow can also be used to thoroughly flush out the boom lines without the need to physically spray on the ground.

- Bank to main tank

- Electric ball valve

- Nozzle body with RapidFire

*RapidFire is not compatible with Direct Chemical Injection (DCI)

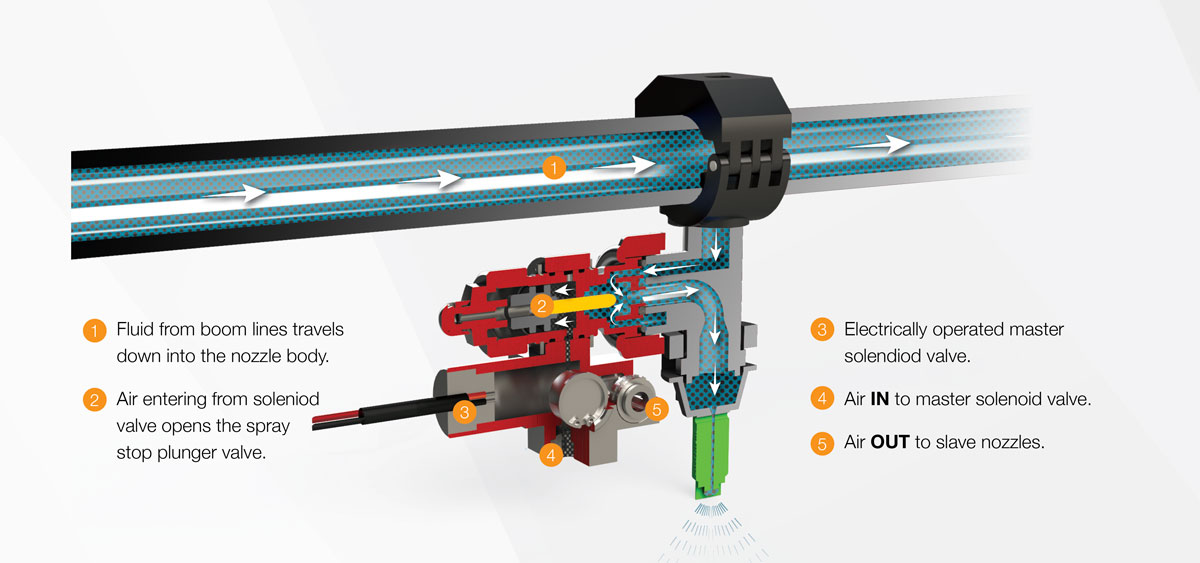

Over the last several years there has been a greater shift to precision farming technologies, such as auto steering and automatic boom section control. Both of these technologies are aimed at reducing spray overlaps and unsprayed areas, the former potentially causing crop burning and overuse of chemical. Depending on the field size and shape the wastage can be quite substantial. Goldacres have developed these practices further by introducing RapidFire air controlled nozzle shut off capability.

Traditional systems use motorised boom section valves to control water flow to the nozzles. Wider booms in conjunction with an increased number of spray sections means a substantial amount of plumbing is required, thus increasing the delay in spray on and off times. In addition, the further the nozzle is from the centre of the boom the longer the delay becomes. RapidFire overcomes these problems by putting the switching capability right at the nozzle.

Small airlines at each nozzle switch the flow on and off in a fraction of a second, and more evenly across the boom width. Boom line plumbing is also greatly reduced, which quickens line priming and flushing as well as simplifies plumbing.

Nozzle technology has advanced in leaps and bounds over the years and a strong emphasis on drift control has influenced many nozzle designs, including air induction (AI) technology

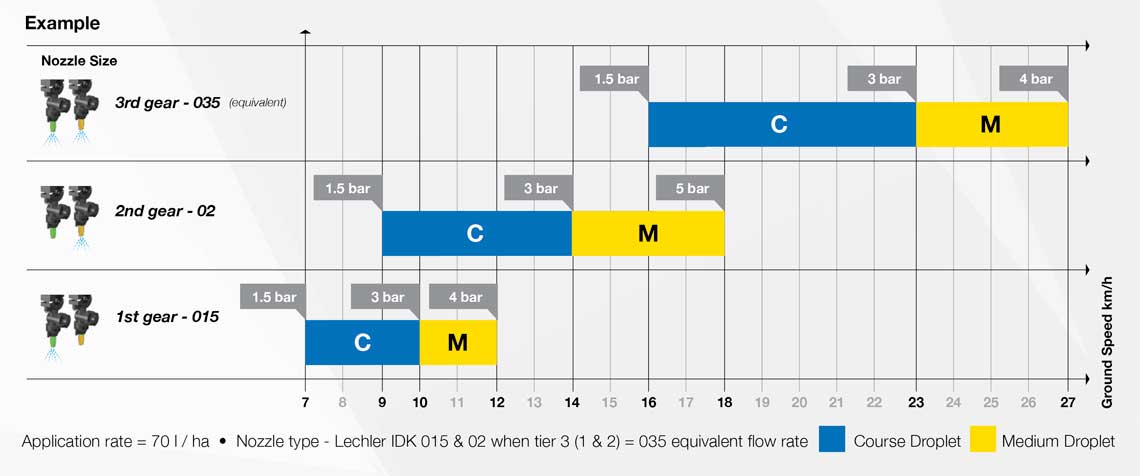

The spray nozzles operating pressure range & size determine the application rate and speed band at which the driver must adhere to. This band is usually quite narrow. Goldacres offer a 3 tier system (3TS) which effectively gives the driver a much wider operating band whilst still maintaining optimum droplet size.

The 3TS system effectively enables the operator to maintain a specific rate across a much wider speed range while delivering a consistent droplet size within the nozzle pressure range.

Think of 3TS as a three-step gearbox. Each nozzle type has an operating pressure band for a given droplet size. As the first nozzle reaches the top of the pressure band it switches off and the next larger size nozzle switches on. When that nozzle reaches the top of that pressure band the first nozzle will switch on again, effectively giving three operating bands.

The table below shows the pressure variations of two common nozzles, 015 & 02 operating at 70 l/ha through their respective pressure ranges from 7 km/h through to 27 km/h.

3TS Pro – the ultimate control and flexibility without leaving the cab.

The 3TS Pro is essentially our 3TS system with an added nozzle to give a wider range of operating spray rates without manually changing jets.

If you are constantly changing rates but want to keep your speed consistent, the 3TS Pro is for you.

For example, you may want to apply 70l/ha with your combination of 015 & 02 nozzles to give the overall capacity of an 035 nozzle (as per 3TS chart shown), then increase your rate in certain parts of the crop, other paddocks or even in the application of fertilisers.

In most cases, you would need to slow down to increase the rate as you would previously exceed the nozzle pressure range. With the additional nozzle, the 3TS Pro will automatically select the best nozzle combinations for your speed and rate while maintaining the working pressure range of the nozzles.

The G6 Crop Cruiser – Series 2, G4 Crop Cruiser – Series 2, G8 Crop Cruiser – Series 3 and G8 Super Cruiser self-propelled sprayer models can now be optioned with Weedetect green on green weed detection spraying system.

The system is available with booms up to and including 36m, with cameras are positioned every three metres and detects weeds at spraying speeds of up to 20kms. Weed detection camera technology provides substantial chemical savings as opposed to blanket spraying, a game-changer for a year-round spraying program.

Raven AutoBoom XRT – Radar boom height sensing technology

- The height sensors are radar-based and enable a large height measurement range, they can detect both ground and crop canopy and are less affected by spray drift, dust and mud. The sensors are also very compact, allowing easy fitment along the boom.

- The Raven XRT system uses sensors to monitor the sprayer chassis rate of roll, the boom centre position relative to the chassis as well as boom wing tilt angle. These sensors allow the computer to predict how the boom will react well before the radar sensors even see the change in boom height. The end result is a more stable boom in uneven terrain.

- The centre section has variable rate dampeners to stiffen the centre section roll action which allows the boom wing tilts to be operated much faster without effecting the boom stability.

- The XRT operating status is displayed on the G-Hub internal screen.

Control fill & cleaning functions from the G-Hub external display.

Simply enter the desired tank volume, connect the fill hose and the G-Hub system will automatically shut off when fill volume is met.

Featuring a full colour 5” screen and button panel to control all fill and clean functions with the push of a button.

Located in the storage compartment, the screen and button panel are mounted on an adjustable RAM bracket which positions the controls at the operator’s ideal location. In addition, the G-Hub system also manages all the liquid control valves which operate all chemical induction, agitation and cleaning functions. Refer to page 39 for details on the valve system.

When your sprayer is sitting idle being reloaded with water and chemical it’s not making you money. That’s why Goldacres offer filling solutions that minimise the reload time to get you back in the paddock sooner.

Options like fully integrated water and chemical transfer pumps, or fast fill 3” systems. Or maybe a separate batching system to complement your spraying program is of interest?

60L Chemical Induction Hopper

The chemical induction hopper is an integrated chemical transfer system that allows liquids, granular and powdered products to be measured and transferred into the main tank. The hopper has 60L capacity with both drum and internal rinsing capabilities. The high flow 3” venturi is mounted at the base of the hopper which draws the chemical into the water stream at that point, minimising the chance of blockages.

A chemical venturi probe can be connected to the induction hopper to draw chemical into the hopper.

Water transfer pump

When you need to transfer water into the sprayer quickly and conveniently the optional hydraulically driven transfer pump is the answer. The pump is plumbed directly to the Fast Fill pod and can distribute flow to not only the main tank but also rinse water tank, main tank flush sprinklers, hopper flush, micromatic coupler and external wash down gun.

A 3″ transfer pump is fitted as standard. This pump combined with high flow plumbing provides flow rates of up to 1150 l/min. Mounted above the pump outlet is a pressure transducer and electric 3” ball valve which is used by the G-Hub system to control both the fill rate and tank level soft shut off.

Operator safety and external controls

Today’s tough OH&S requirements are there to ensure everyone finishes the day like they started. Safe and well. At Goldacres we not only take care of our own employees, but we ensure operators of our products are also looked after. Clearly labelled Fast Fill control station, well laid out connection points and valves at correct working heights, personal protective equipment (PPE) locker, hand washing and empty container rinsing equipment just to name a few. External switches with protective covers allow the operator to increase engine RPM, switch on the transfer pump and control the main sprayer pump, all from ground level.

Liquid Chemical Transfer Systems

When large quantities of neat chemical need to be transferred into the sprayer from either a 1000L intermediate bulk container (IBC), 110L enviro drum or just a standard 20L drum then the chemical venturi probe or optional micromatic coupler can be used. The micromatic coupler arrangement is a complete closed-loop connection system that eliminates the chance of the operator coming into contact with the chemical. The main sprayer pump is used to generate flow through a venturi, which creates a vacuum for the chemical to be drawn in. At no stage does the chemical come into contact with the pump and is therefore virtually a maintenance-free system.

Chemical transfer pump

Neat chemical transfer is done using a Graco pneumatic twin diaphragm high capacity pump (fitted as standard). The pump features large-diameter diaphragms to create large amounts of suction, ideal for high viscosity chemicals. The neat chemical can be delivered directly to the product tank or diverted to the chemical induction hopper where it can be measured and then transferred to the product tank. Tests have shown 40 l/min of high viscosity chemicals can be transferred.

Spray pump

A choice of two different spray pumps can be fitted. A Udor Zeta 260 l/min pump now featuring Greentech diaphragms for increased life. The diaphragm pump provides constant flow rates regardless of spray pressure. Tests have shown that flow rates of 220 l/min out the boom is now possible, that equates to 100 l/ha @ 35 km/hr with a 36m boom (nozzle dependant).

The second pump is a high flow centrifugal pump, flow rates of 400 l/min @8 bar are achievable with this pump. Both pumps feature rpm and run dry sensors which are displayed on the G-Hub cabin display.

Storage locker

- A large lockable storage compartment is provided and features a gas strut to hold open the door.

- It’s also the location of the G-Hub external display and button panel.

Micromatic rinse socket

Standard fitment.

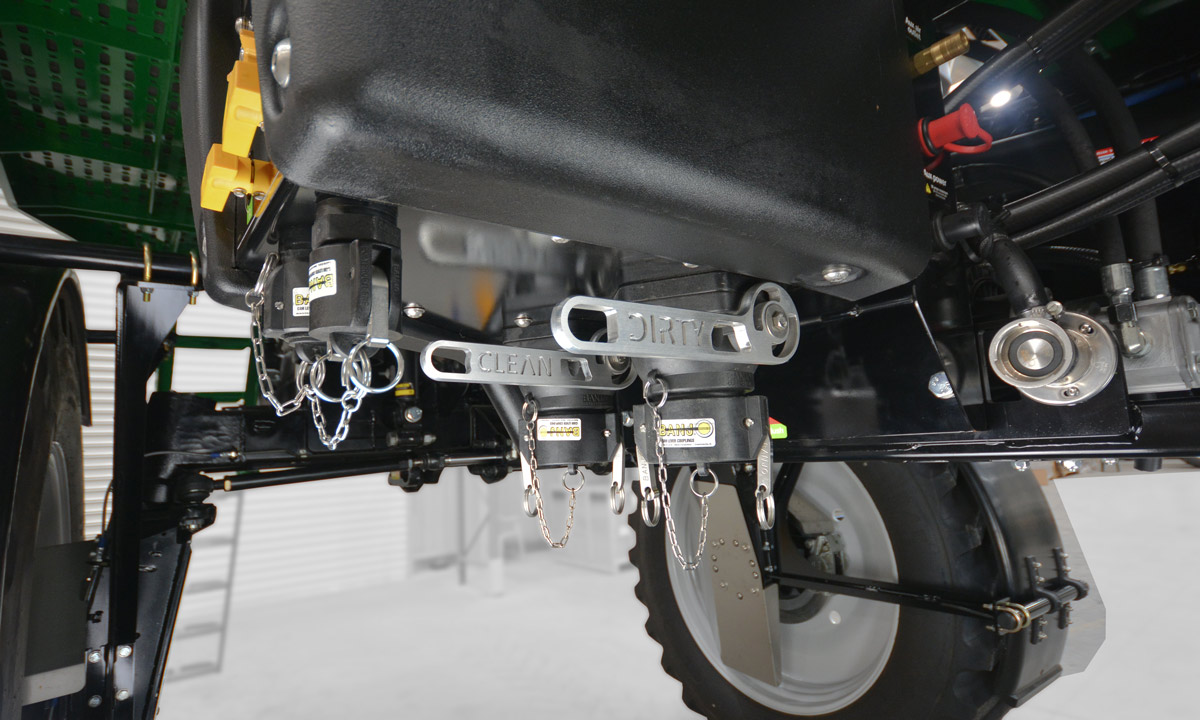

Product tank filling is now 3” and features “clean” and “dirty” connection points

- Clean point is for clean water suction via the on-board fill pump. Clean water can be distributed throughout the sprayer.

- Dirty point is for pre-mixed water and chemical transferred directly into the main product tank from a batching plant.

In both cases the auto tank filling feature is available to use.

Manual valves are used to direct the chemical from the transfer pump and the probe connection points.

Whether you are spraying in the field or driving down the road, uninterrupted vision around the sprayer is essential for the safety of you and others

Features like the flat folding boom wings so the operator’s line of sight is uninterrupted. Electrically adjustable side mirrors provide a clear view of the road behind. 360º rotation windscreen wiper blade for maximum cleaning area of the front window. Hydraulically adjustable LHS boom rest provides the operator with easy access to the cabin in the wide position yet brings the overall transport width down for road transport to under 3.5m*, eliminating the need for an escort vehicle. Twin circuit, 4 wheel disc brakes fitted as standard. LED daytime running lamps, turn indicators, high / low beam projector style halogen head lights and twin rotating warning beacons round out the package. The Crop Cruiser really is one for the road.

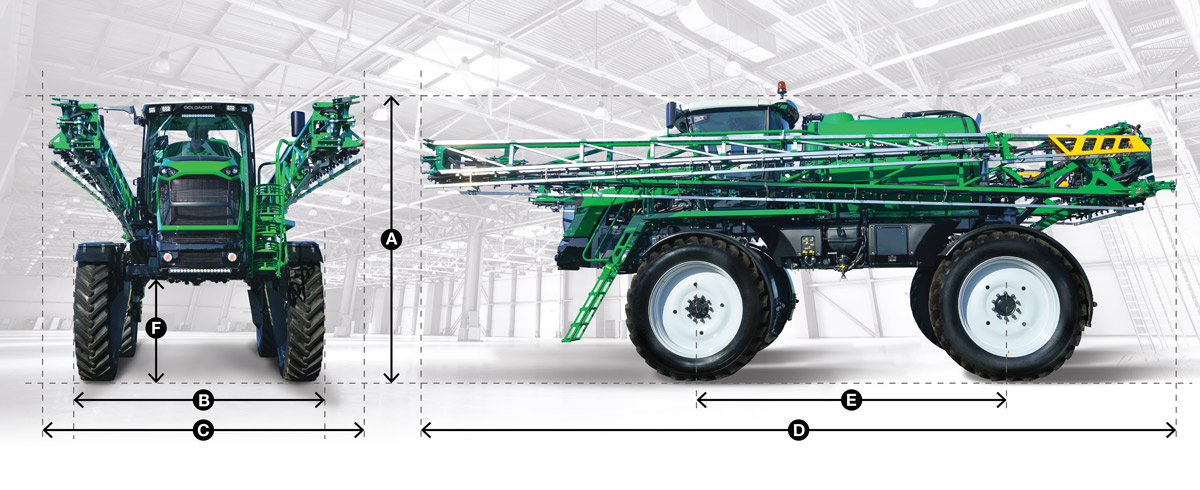

| Dimensions | A (mm) airbags inflated | A (mm) airbags deflated | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) |

|---|---|---|---|---|---|---|---|

| 36m Boom | 4150 | 4050 | 3500 | 3400 | 9315 | 4200 | 1460 |

| 42m Boom | 4150 | 4050 | 3500 | 3400 | 10585 | 4200 | 1460 |

| 48m Boom | 4150 | 4050 | 3500 | 4200 | 9350 | 4200 | 1460 |

All dimensions measured with 480/85R50 Tyres fitted @ 2970mm wheel centres

| Feature | Description | G6 |

|---|---|---|

| Engine | Cummins QSB 6.7L, 6 cylinder, Tier 3 emission. 168kw (225hp), 949N.m (700lb-ft) | Standard |

| Vertically stacked combi cooler package. Fuel, transmission, water jacket, charge air & air conditioning | Standard | |

| Variable speed hydraulic driven cooling fan | Standard | |

| Transmission | Allison 2500 series automatic. Push button selector, lock up torque converter, 6 forward & 1 reverse | Standard |

| Drive system | 4.4:1 final drive leg with oil bath lubrication | Standard |

| 2 wheel drive with LSD 5.125:1 ratio | Standard | |

| Full-time 4 wheel drive system with centre diff lock | Standard | |

| Fuel tank | 440L | Standard |

| Steering | 2 wheel front steering system with true Ackerman alignment | Standard |

| 2 wheel front steering system with true Ackerman alignment | Standard | |

| Hydraulics | 100L plastic reservoir with level & temperature sensors | Standard |

| Twin gear pumps 22 and 32 cc/rev | Standard | |

| Single variable displacement pump 45 cc /rev | Standard | |

| Rear mount oil cooler with thermostat | Standard | |

| 3 x pressure filters, 1 x tank mounted return filter | Standard | |

| Electrical system | 12V – 200amp electrical capacity | |

| Dual batteries with master isolator | Standard | |

| Fully sealed connectors with colour coded wires used throughout the wiring harness | Standard | |

| 6 x LED cabin lights | Standard | |

| 3 x LED service lights | Standard | |

| LED light bar for lower bonnet (18 x 10W CREE) | Option | |

| LED light bar for upper cabin (12 x 10W CREE) | Option | |

| Braking system | Full hydraulic brake circuit | Standard |

| 4 wheel disc | Standard | |

| Spring operated diff mounted disc park brake | Standard | |

| Chassis | Fully welded semi truss rigid mild steel | |

| 200 x 100 x 9mm main rails | ||

| Suspension | 5 link torque rods with rear sway bar. 4 x rolling lobe air springs with ride height levelling. Shock absorbers on all corners, front feature double knuckle for extreme axle articulation. | Standard |

| Paint system | Grit blasted steel work followed by high build primer. | Standard |

| All unwelded sections seam sealed. | Standard | |

| Wet top coat paint system with high temperature baked finish | Standard | |

| Wheel Equipment | 16mm pressed centre, 10 studs on 335mm PCD (min 16mm) | Standard |

| 480/80R46 (166A8/159D) | Standard | |

| 520/85R46 (173A8/169D) | Option | |

| 480/80R50 (177A8/166D) | Option | |

| Axle tracks | Axle track widths are dependent on tyre width selected | |

| 2970mm fixed wheel track | Standard | |

| 3048mm (120″) fixed wheel track (uses offset wheels) | Option | |

| Mudguards | 4 x full length axle mounted polyethylene mudguards | Standard |

| Deflectors | 4 x leading edge stainless steel crop deflectors | Standard |

| 4 x brake mud shields | Standard | |

| Crop dividers for front wheels | Option | |

| Crop dividers for rear wheels | Option | |

| Cabin | Business class styled cabin with suspension | Standard |

| Dual tilt and telescopic steering column | Standard | |

| Air suspension seat with seat belt. Fully adjustable | Standard | |

| Training seat with seat belt | Standard | |

| Accessory mounting rail on RHS | Standard | |

| Carbon filtration with positive cab pressurisation | Standard | |

| Bluetooth equipped radio and UHF with high gain antennas | Standard | |

| Refrigerator module for storage compartment under training seat | Option | |

| Window tint for all 4 sides | Option | |

| Main cabin access | Full length LHS access platform with auto folding ladder. Hydraulically adjustable width LHS boom rest for ease of access and convenient road transport. Rubber dampened hand rail. | Standard |

| RHS service platform with manual fold up ladder | Option | |

| Boom | TriTech RivX boom (36 & 42m). Mild steel inner wings with aluminium/steel outer wings & breakaway. | Standard |

| 48m TriTech V boom (3 spray widths. 20m, 36m & 48m). Mild steel inner wings with aluminium mid, outer wings and breakaway. | Option | |

| Available in the following widths. 36, 42 & 48m. All booms plumbed in 16 sections – no “Extra boom sections available” | Standard | |

| RapidFire single line in 500mm spacing | Standard | |

| RapidFlow boom recirculation | Standard | |

| 3 tier system (3TS) | Option | |

| 3 tier system PRO (3TS PRO) | Option | |

| Raven Hawkeye PWM with turn compensation | Option | |

| Weedetect – Green on Green / Green on Brown weed detection system | Option | |

| Trijet nozzle bodies | Option | |

| Cross fire 3TS (3TS capability with nozzles staggered every 250mm) | Option | |

| Custom nozzle spacing and configurations on request | Option | |

| Hydraulic wing tilt | Standard | |

| Hydraulic bi-fold | Standard | |

| Hydraulic yaw system | Standard | |

| Automatic boom height control system (standard on 48m) | Option | |

| Remote fence line jets (both sides) | Standard | |

| Control system | G-Hub – Goldacres Integrated System | Standard |

| ISOBus control system using Raven RCM (CR7 separate VT option) | Standard | |

| Solution tanks | UV stable Polyethylene heavy walled tank. Supported in a steel cradle | Standard |

| Main tank – 6000L | Standard | |

| Rinse tank – 550L side mount | Standard | |

| Electronic tank measurement | Standard | |

| Spray Pump | 260 l/min, oil backed 6 diaphragm positive displacement. RPM readout | Standard |

| High flow centrifugal pump (standard on 48m boom) | Option | |

| Suction filter plus self cleaning pressure filter, electric switching between all functions | Standard | |

| Chemical handling and transfer | Chemical suction probe via Graco chemical pump | Standard |

| 60L induction hopper | Standard | |

| Micromatic rinse socket and coupler | Standard | |

| 3” integrated water transfer pump | Standard | |

| 3” separate front fill direct to tank | Option | |

| 3” side fill with twin points with auto shut-off (clean and dirty lines) | Standard | |

| Service / Maintenance | Remote grease nipple bank | Standard |

| Auto grease system | Option | |

| Turning circle | 18m curb to curb 3m axle with 480/80R46 wheels (2WD) | |

| Tare weight | 11,800kg* | |

| Gross weight | 18,790kg* |

*Weights based on 6000L 36m boom 2WD are approx. and depend on options fitted

- G6 Crop Cruiser

- 2021

- 0

- GA8701332

- 23mb

- View Online

- Download

- Customer Testimonial

- TV Advert

- Fast Fill - How to

- Induction Hopper - How to

Reviews

There are no reviews yet.