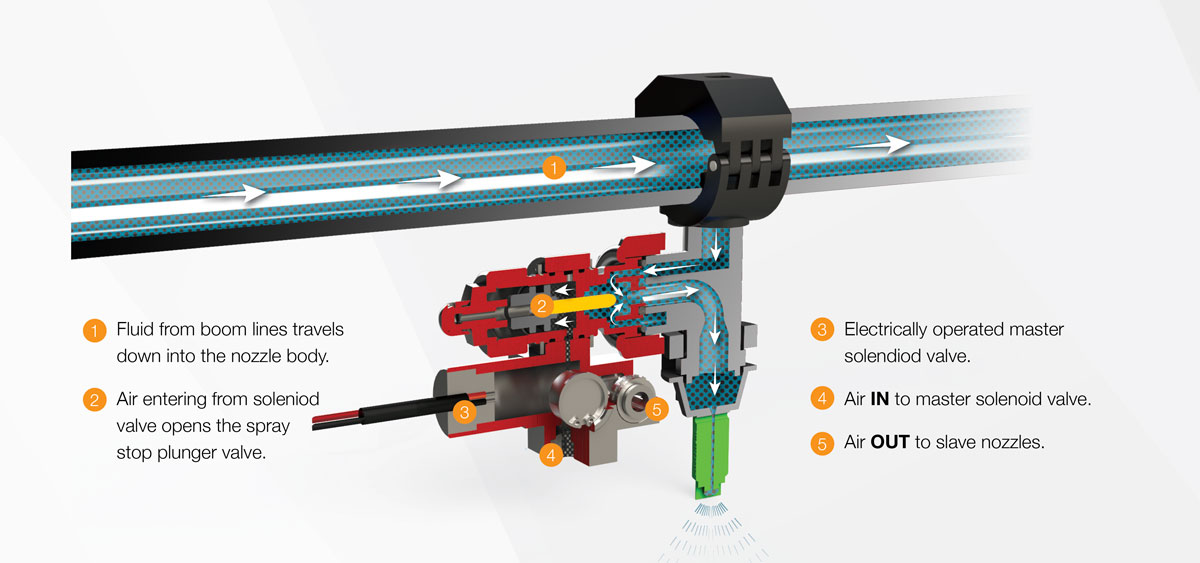

Small airlines at each nozzle switch the flow on and off in a fraction of a second, and more evenly across the boom width. Boom line plumbing is also greatly reduced, which quickens line priming and flushing as well as simplifies plumbing.

Over the last several years there has been a greater shift to precision farming technologies, such as auto-steering and automatic boom section control. Both of these technologies are aimed at reducing spray overlaps and unsprayed areas, the former potentially causing crop burning and overuse of chemical. Depending on the field size and shape the wastage can be quite substantial. Goldacres have developed these practices further by introducing RapidFire air controlled nozzle shut off capability.

Traditional systems use motorised boom section valves to control water flow to the nozzles. Wider booms in conjunction with an increased number of spray sections mean a substantial amount of plumbing is required, thus increasing the delay in spray on and off times. In addition, the further the nozzle is from the centre of the boom the longer the delay becomes. RapidFire overcomes these problems by putting the switching capability right at the nozzle.

| Sprayer | Compatable |

|---|---|

| Prairie Pro | ✓ |

| G4 Crop Cruiser | ✓ |

| G6 Crop Cruiser | ✓ |

| G8 Crop Cruiser | ✓ |