MY 23 Prairie Special Series 2. Greater Range, greater control & still simple to operate.

The Special is a totally new beast, the large frame Prairie Special now consists of 4000, 5000, 6500, 8500 & 10,000L tank capacities with boom sizes 24m to 36m.

Clever in design, simple in functionality, the special shares many design elements with its high-tech brother, the recently released Prairie Pro Series 2.

The new Prairie Special Series 2 features a totally new chassis and adjustable height pull to adapt to different tractor drawbars. The pull is a narrow design and a large rinse tank fitted under the sprayer platform. A new higher platform and boom rest design radically cleans up the appearance of the machine whilst making access to the tank much easier.

All sprayer plumbing is designed to allow for higher fill and application rates. Fitted with an IsoBus controller and boom plumbing in 5 sections standard or the option of 10 sections with the Goldacres RapidFire nozzle switching and RapidFlow boom recirculation and 3TS nozzle technology.

First of new models to hit the production line are the 5000 & 6500L large frame Specials.

In “Limited Edition” specification.

The 5000L model is fitted with the 30m Tritech boom while the 6500L is fitted with a 36m Boom.

Specs remain the same on both models with 5 section 3TS plumbing, with Rapid Fire and Rapid flow spraying technology, dual-sided electric fence line nozzles, 60L Induction hopper, Electric over hydraulic valve block, individual wing tilt, Airbag 2mtr axles with 18.4 x 38 wheels and mudguards,

3” high flow Fill Pump, hydraulic drive Zeta 260 Diaphragm pump and ISOBus PC1 sprayer control system.

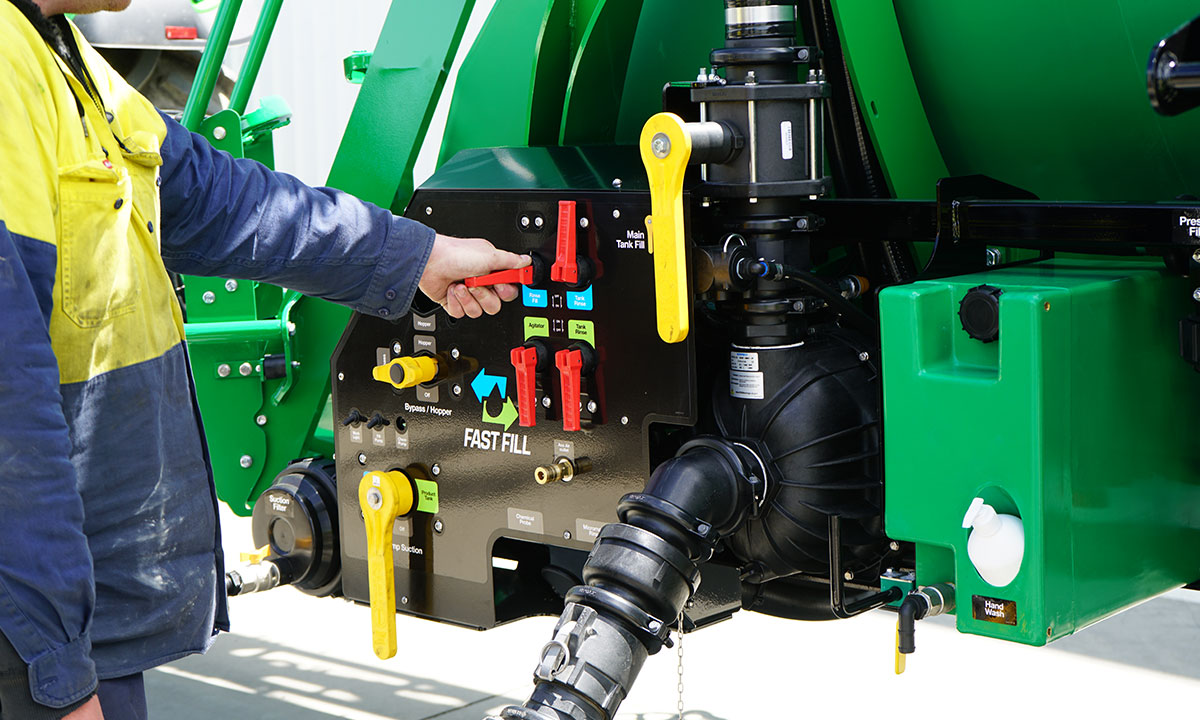

As the name suggests, the filling pod on the Special is fast, located on the left-hand side of the sprayer fast fill incorporates all filling functions into the one area.

Flip leavers and ball valves control all functions with a 3” Fill line to ensure large capacities can flow into the sprayer, or you can select the option of a 3” hydraulic fill pump offering up to 1150l/min.

Fill pump (optional)

A Hypro 3” transfer pump can now be fitted. This pump combined with high flow plumbing provides flow rates of up to 1150 l/min.

Airbag Suspension

Latest design uses a twin Hendrickson airbag design with an air reservoir tank and ride height valves.

4000, 5000 & 6500L is manufactured with 9mm wall 150 x 100mm RHS and 90mm series stubs, while the larger capacity units, 8500 & 10,000L use 9mm wall 250 x 150mm RHS with 110mm series stubs.

60L Induction Hopper

- 60L capacity

- Chemical transfer rates of up to 150 l/min. (depend on chemical viscosity)

- Chemical induction can also be done via the probe directly into the hopper base

- Foot-operated lower shutoff valve.

- Wash down gun powered by separate 12-volt pump using water from rinse tank.

Proven Performer with the option of Rapid Fire, Rapid Flow & 3TS

Boom sizes in the model line-up are 24, 28, 30, 33 & 36 meters.

Boom control can be the difference between a good spray result, and no result at all. Goldacres understand this and it is why all our sprayer designs are centred around the boom first and foremost.

Goldacres pioneered the use of lightweight aluminium in the outer boom wings over two decades ago.

The philosophy was and still is today that mass on a boom is fine so long as it is as close to the centre as possible. Reduced mass on the boom extremities reduces boom forces in both yaw and roll. This combined with the unique boom suspension results in a very stable boom ride, regardless of the terrain.

TriTech booms are contour following, meaning that the boom level will be referenced to the sprayer chassis and not purely on gravity such as a pendulum boom. This allows the sprayer to transverse the sides of hills and contours whilst keeping the boom level to the ground at all times. This results in placing the nozzle at the optimum height above the target.

The TriTech boom range is designed for operators who demand the utmost performance, reliability and control. Time and time again the TriTech boom has been named “No.1 for boom stability”* which at the end of the day, results in a superior spray result.

Features such as hydraulic yaw which precisely controls the forwards and backwards movement of the boom wings to minimise the under and over applying of chemical are now standard on all widths.

The strategically placed centre section suspension links help isolate the sprayer chassis movement over rough terrain. Combined with the tuned damping characteristics allows precise roll control enabling an optimal and consistent nozzle height to be maintained, even without the use of electronic height control systems.**

All TriTech booms are constructed using lightweight trussing techniques, which allows for a stronger design without weight, the enemy of boom agility.

Boom stability is only part of the chemical application story, optimum droplet sizing, pressure, nozzle flow rate and spray uniformity across the boom width are all critical to accurate chemical application.

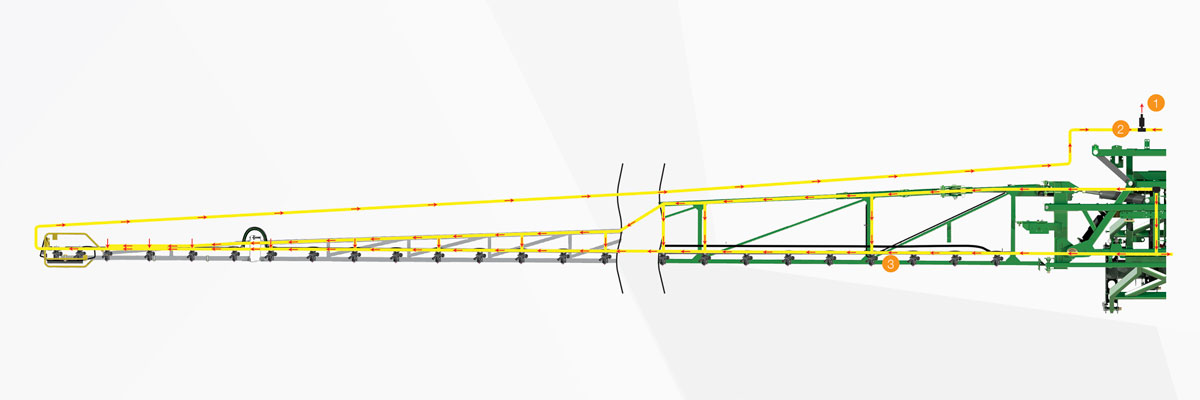

RapidFlow – Boom Recirculation* allows the sprayer boom lines to be fully primed without spraying a single drop. This reduces wastage at the start of a tank load or when switching chemicals. RapidFlow can also be used to thoroughly flush out the boom lines without the need to physically spray on the ground.

- Bank to main tank

- Electric ball valve

- Nozzle body with RapidFire

*RapidFire is not compatible with Direct Chemical Injection (DCI)

Over the last several years there has been a greater shift to precision farming technologies, such as auto-steering and automatic boom section control. Both of these technologies are aimed at reducing spray overlaps and unsprayed areas, the former potentially causing crop burning and overuse of chemical. Depending on the field size and shape the wastage can be quite substantial.

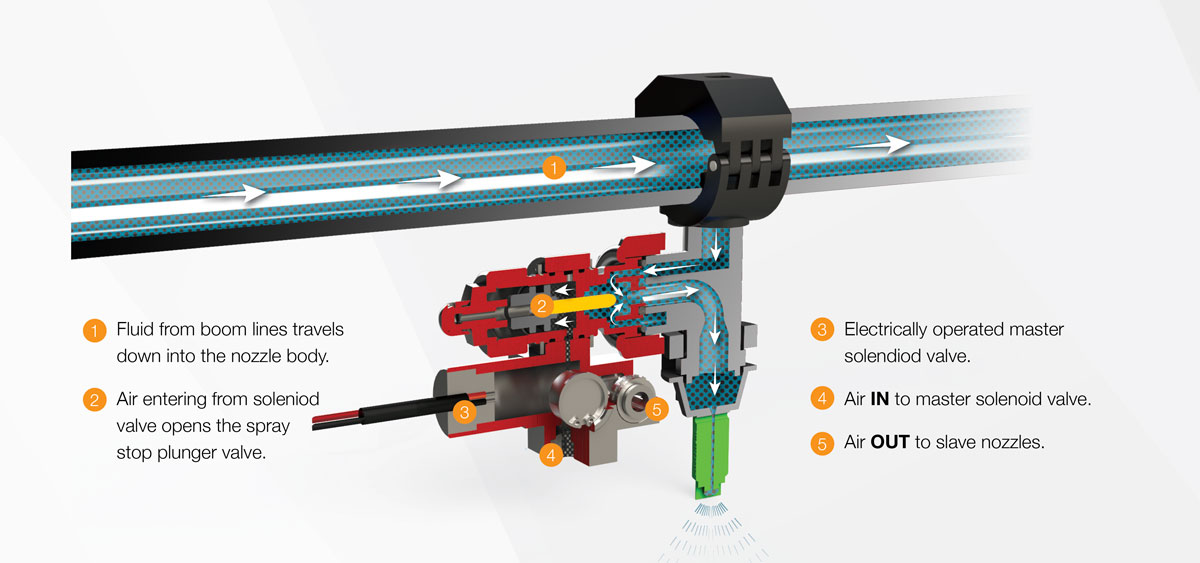

Goldacres have developed these practices further by introducing RapidFire air-controlled nozzle shut-off capability. Traditional systems use motorised boom section valves to control water flow to the nozzles. Wider booms in conjunction with an increased number of spray sections means a substantial amount of plumbing is required, thus increasing the delay in spray on and off times. In addition, the further the nozzle is from the centre of the boom the longer the delay becomes.

RapidFire overcomes these problems by putting the switching capability right at the nozzle. Small airlines at each nozzle switch the flow on and off in a fraction of a second, and more evenly across the boom width. Boom line plumbing is also greatly reduced, which quickens line priming and flushing as well as simplifies plumbing.

Nozzle technology has advanced in leaps and bounds over the years and a strong emphasis on drift control has influenced many nozzle designs, including air induction (AI) technology.

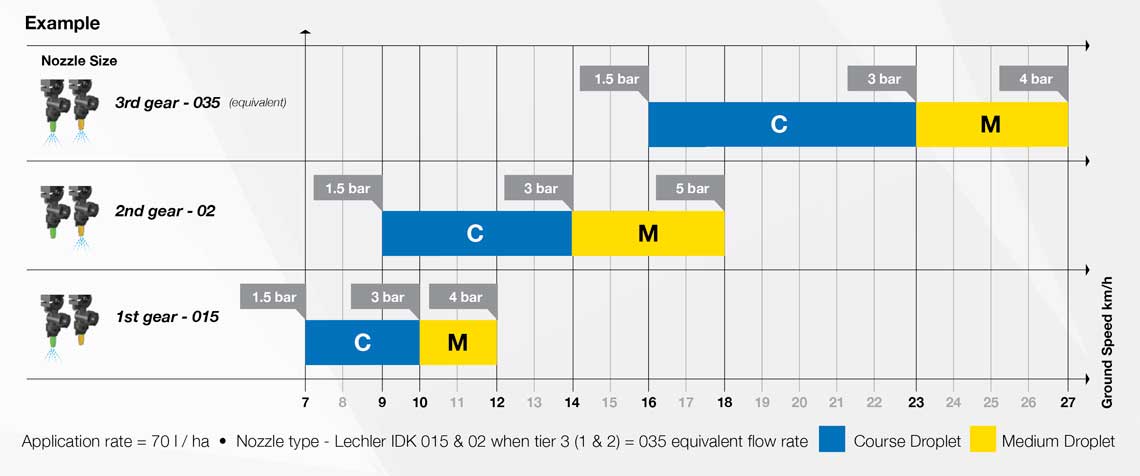

The spray nozzles operating pressure range & size determine the application rate and speed band at which the driver must adhere to. This band is usually quite narrow. Goldacres offer a 3 tier system (3TS) which effectively gives the driver a much wider operating band whilst still maintaining optimum droplet size.

The 3TS system effectively enables the operator to maintain a specific rate across a much wider speed range while delivering a consistent droplet size within the nozzle pressure range.

Think of 3TS as a three-step gearbox. Each nozzle type has an operating pressure band for a given droplet size. As the first nozzle reaches the top of the pressure band it switches off and the next larger size nozzle switches on. When that nozzle reaches the top of that pressure band the first nozzle will switch on again, effectively giving three operating bands.

The table above shows the pressure variations of two common nozzles, 015 & 02 operating at 70 l/ha through their respective pressure ranges from 7 km/h through to 27 km/h.

| 4000L | 5000L | 6500L | 8500L | 10,000L | |

|---|---|---|---|---|---|

| Boom Options | |||||

| 24m TriTech boom | Optional | N/A | |||

| 28m TriTech boom | Optional | N/A | |||

| 30m TriTech boom | Optional | ||||

| 36m TriTech boom | Optional | ||||

| Single-sided solenoid fence line | Optional | ||||

| Dual-sided solenoid fence line | Optional | ||||

| 500mm broadacre plumbing | Standard | ||||

| 500mm rowcrop plumbing (centre) | Optional | ||||

| Remote grease nipple bank | Optional | ||||

| Boom wing tilt | Optional | ||||

| Boom Bi-fold | Optional | ||||

| XRT Height control system in 5 sensor | Optional | ||||

| 18.4 x 38 | Standard | N/A | |||

| 480/80R46 HR45 166A8/159D | Optional | N/A | |||

| 480/80R50 HR45 X-load 177A8 TL | N/A | Optional | |||

| 520/85R42 HR45 X-Load 169A8 | Optional | Standard | N/A | ||

| 520/85R46 173A8/169D | N/A | Optional | N/A | ||

| 710/70R42 | N/A | Optional | Standard | ||

| Rigid Axle | Standard | N/A | |||

| Air bag suspension | Optional | Standard | |||

| Axle width 2m | Standard | N/A | |||

| Axle width 2.2m | N/A | Standard | |||

| Axle width 3m | Optional | ||||

| Customer specified width | Optional | ||||

| Mudguards | Optional | ||||

| Hydraulic brakes | Optional | Standard | |||

| Induction Hopper | |||||

| Pentair fill pump 3″ | Optional | ||||

| Electric chemical transfer pump | Optional | ||||

| Micromatic rinse socket | Optional | ||||

| Sprayer Controls & Connections | |||||

| RISO BUS system – No VT (Non-RCM) | Standard | ||||

| Pump Options | |||||

| 260 l/min PTO pump – wide angle drive shaft | Standard | N/A | |||

| 260 l/min hydraulic drive pump | Optional | N/A | |||

| Multi-stage centrifugal pump 400 l/min | Optional | Standard | |||

| Manual wind jack | Standard | N/A | |||

| Hydraulic jack | Optional | Standard | |||

- Prairie Special Series 2