The Super Cruiser is a clean sheet design, while drawing on proven elements from the successful Crop Cruiser range, yet centred around an 8000L main tank. The final product is uncompromising in terms of strength, performance, weight balance, efficiency, stability, visibility, styling, comfort and functionality.

When Goldacres designers and engineers set out to develop the G8 Super Cruiser they knew that a simple cut and shut approach would not deliver the desired results.

The Super Cruiser is a clean sheet design, while drawing on proven elements from the successful Crop Cruiser range, yet centred around an 8000L main tank. The final product is uncompromising in terms of strength, performance, weight balance, efficiency, stability, visibility, styling, comfort and functionality.

Centrally located cabin with suspension and an air ride seat to help reduce operator fatigue, mechanical driveline is also quieter by design.

The sprayer is one of the most utilised items of equipment on the farm today. Long hours day after day, places plenty of demand on the operator to get the spraying program completed.

The G8 Super Cruiser cabin makes it all possible, with features like:

- Seven way adjustable seat

- Adjustable side console with G-Motion joystick.

- Automatic climate control air-conditioning system with carbon filter.

- Adjustable steering column ensures operators can find the optimal seating position.

- Padded training seat with seatbelt.

- Narrow profile four post frame with external truss Roll Over Protective Structure (ROPS).

- Double skinned rear wall and extensive sound deadening provide a strong, yet peaceful uninterrupted view of the job at hand.

The high mounted, centrally positioned cabin gives the operator visibility where it counts.

The cabin is mounted high on the chassis, with the bonnet mounted low. This gives an almost completely uninterrupted view from the front window. Visibility through the side and rear windows provides an excellent view of the boom.

The main access platform features longitudinal slots to see through. Curved glass on all four sides with strategically placed narrow profile four post ROPS frame.

The hydraulic reservoir with volume level with temperature gauge and back lit spray pressure gauge are clearly visible.

Multiple suspension systems along with cabin position on the chassis give the operator a smooth comfortable ride.

A cabin positioned behind the front axle gives a naturally superior ride due to the reduced vertical movement. In addition, the suspended cabin, air seat and five link air bag chassis suspension system give the operator a smooth, comfortable ride.

Seven way adjustable seat, adjustable side console, adjustable G-Motion™ handle position and adjustable steering column ensure operators of all sizes can find a place to do their best work.

- Air ride suspension seat

- Suspended cabin

- Five link suspension with torque rods, rear anti-sway bar with air bags on all four corners

- TriTech boom suspension controlling pitch, roll and yaw

We know that one size does not fit all

Seven way adjustable seat, adjustable side console, adjustable G-Motion™ handle position and adjustable steering column ensure operators of all sizes can find a place to do their best work.

Two’s not a crowd

When the days are long and a bit of company is needed it’s nice to have a proper place for someone to sit. The padded training seat with seatbelt is large and comfortable without hindering the operator’s vision or space. The seat also folds away to reveal a large storage area with optional cooling module for food and beverages.

Keep your cool

The Australian summers can be long and hot, but that doesn’t mean you should be. The fully integrated automatic climate controlled air conditioning system with carbon filter allows the operator to set and forget. Strategically placed air ducting ensures air movement is even around the cabin. There’s even an overhead cooled storage compartment for a drink bottle.

Operator side console enables simple operation and functionality of all vital sprayer functions.

- Adjustable mounting of sprayer console is in line of sight, but low enough so it does not hinder the outside view.

- Multifunction engine and transmission monitor puts vital information at your fingertips.

- Push button transmission selector. Displays selected and actual gear.

- G-Motion™ handle. Adjustable position caters for all operators. Boom folding functions.

- Various machine functions like spray pump on/off, centre diff lock and boom recirculation just to name a few.

- Hinged padded arm rest which reveals a large storage area.

Comfortable, adjustable and intuitive.

The new G-Motion™ handle literally puts the sprayer control into the palm of your hand. Functions such as: Individual boom wing tilt, dual boom wing tilt, main boom lift/lower, fence line L/R, auto steer cancel/resume, cruise control set/resume and increase/decrease, master spray on/off mean all spraying operations can be done without moving your hand from the G-Motion™ handle.

- Cruise Set / Increase

- Cruise Resume / Decrease

- Cruise Cancel

- Boom Master On / Off

- Tilt Right Up, Tilt Left up

- Tilt Right Down, Tilt Left Down

- Boom Lift, Left Fence Nozzle

- Right Fence Nozzle, Boom Lower

- GPS Auto Steer

- Dual Tilt Up (Behind)

- Dual Tilt Down (Behind)

Introducing the latest in ISO BUS technology, the Raven RCM controller.

The ISO BUS standard is now considered the platform of choice for sprayer operators. It allows multiple brands of sub systems to all communicate through the one console. This allows operators to use the same preferred console across many pieces of farm machinery.

The latest iteration of this platform is the Raven Control Module (RCM). The RCM uses Raven’s latest technology and brings many new features to help make precision farming simpler. Features such as:

Dual screen capability: with so many systems on the sprayer some consoles can struggle to display all the information easily. With the two screens the operator can choose which information they would like to display on which console. For example, the mapping and guidance information could be displayed on the larger screen whilst rate information displayed on a smaller CR7 screen.

16 boom section control: Control up to 16 sections in single line 3TS or the new 3TS Pro (3 nozzle system). Smarter internal circuitry has eliminated the “smart box” nozzle switching hardware which increases system reliability.

Bluetooth connectivity allows operators to connect their phone or tablet to the sprayer for remote nozzle checking. This greatly speeds up the nozzle checking operation.

When your sprayer is sitting idle being reloaded with water and chemical it’s not making you money. That’s why Goldacres offer filling solutions that minimise the reload time to have you back in the paddock sooner.

Options like fully integrated water and chemical transfer pumps, or fast fill 3” systems. Or maybe a separate batching system to complement your spraying program is of interest?

SuperFlow chemical induction hopper

The SuperFlow chemical induction hopper is an integrated chemical transfer system that allows liquids, granular and powdered products to be measured and transferred into the main tank. The hopper has 60L capacity with both drum and internal rinsing capabilities. The high flow 2” venturi is mounted at the base of the hopper which draws the chemical into the water stream at that point, minimising the chance of blockages.

Water transfer pump

When you need to transfer water into the sprayer quickly and conveniently the optional hydraulically driven transfer pump is the answer. The pump is plumbed directly to the EZ control pod and can distribute flow to not only the main tank but also rinse water tank, main tank flush sprinklers, hopper flush, micromatic coupler and external wash down gun.

Operator safety and external controls

Today’s tough OH&S requirements are there to ensure everyone finishes the day like they started. Safe and well.

At Goldacres we not only take care of our own employees, but we ensure operators of our products are also looked after. Features such as the clearly labelled and colour coded EZ control pod, well laid out connection points and valves at correct working heights, personal protective equipment (PPE) locker, hand washing and empty container rinsing equipment just to name a few. External switches with protective covers allow the operator to increase engine RPM, switch on the transfer pump and control the main sprayer pump, all from ground level.

Liquid chemical transfer systems

When large quantities of neat chemical need to be transferred into the sprayer from either a 1000L intermediate bulk container (IBC), 110L envirodrum or a standard 20L drum then the chemical venturi probe or optional micromatic coupler can be used. The micromatic coupler arrangement is a complete closed loop connection system that eliminates the chance of the operator coming into contact with the chemical. The main sprayer pump is used to generate flow through a venturi, which creates a vacuum for the chemical to be drawn in. At no stage does the chemical come into contact with the pump and is therefore virtually a maintenance free system.

If you require a separate system then a 12 volt chemical transfer pump and counter arrangement can be fitted. Both the probe and micromatic coupler can be used.

Providing the foundation for the machine is the rigid chassis, suspension, and mechanical driveline.

The main chassis is a fully welded, torsionally rigid semi truss structure. This offers not only the best sprayer and boom ride, but also the optimum balance between strength and weight. The proven 5 link suspension featuring polyurethane bushed heavy duty torque rods, rear anti-sway bar and air springs on all four corners provides a stable smooth ride. All this combined with the full mechanical driveline results in performance on the ground.

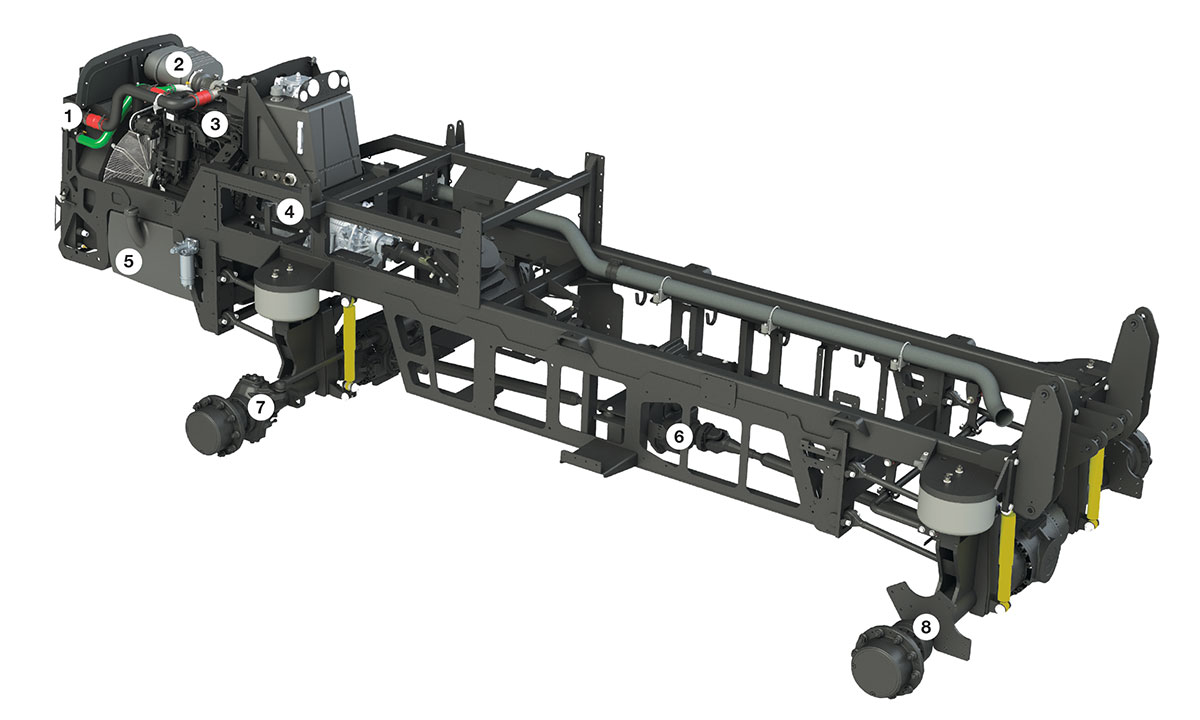

1 Cooling System

Large vertically stacked cooling system for fuel, transmission, water jacket, charge air and air conditioning. Optimised cooling fan to reduce noise whilst still providing maximum air flow.

2 Over the Radiator Air Cleaner System

Has twin stage filtration provides cool clean air to the engine.

3 Engine

Cummins Tier 3 QSB 6.7L – 6 cylinder engine rated to 194kw (260hp) and 987N.m (728 lb-ft).

4 Transmission

Allison 3000 series 6 speed automatic transmission with electronic push button selector. Double overdrive reduces engine RPM whilst still maintaining 50km/hr transport speed. Lock up torque converter improves performance whilst drastically reducing heat build up and fuel usage.

5 Fuel Tank

300L polyethylene fuel tank with both left & right hand side filling points provides enough fuel for the longest spray days.

6 4WD (Full-time)

Lockable centre differential provides a 50/50 power split between front and rear axles. An internal ratio step down of 30% reduces drive shaft speed, resulting in longer universal joint life, reduced noise, vibration and harshness (NVH).

7 Front Axle

Front axle features extreme rated planet hub reduction design with internal wet multi disc brakes. Fully incorporated suspension mountings and mechanical link between front wheels ensures correct Ackerman angles and alignment.

8 Rear Axle

Rear axle features extreme rated planet hub reduction design with internal wet multi disc brakes, negative park brake and differential lock. Fully incorporated suspension mountings including the anti-sway bar and tow bar point round out the package.

Today’s farmer must evaluate capital equipment purchases carefully to ensure that the return on investment is maximised.

With all the models and options available today the choice has never been greater, or harder. Look past the sticker price of the initial purchase, dig a little deeper and substantial variations in sprayer design can make all the difference.

This is where the Goldacres Super Cruiser mechanical drive line system sets it apart from its hydrostatic drive competitors.

There are numerous benefits with a mechanical drive sprayer, such as:

- Less maintenance costs

- Less noise

- Significant fuel reduction

- Less heat generated

- Lower engine rpm

- Lower horsepower required

- More torque at the wheels

- Longer component life.

These all equate to substantially lower operating costs. Reports back from owners state that the Goldacres Super Cruiser can use up to a third of the fuel than some hydrostatic drive sprayers in the same situation. So when the time comes to make that important purchase, dig a little deeper and turn the Goldacres mechanical advantage into your advantage

Perfect weight distribution provides superior sprayer performance and operator comfort.

The cabin is mounted behind the front axle to give a naturally superior ride due to reduced vertical movement. In addition, the suspended cabin, air seat and five link airbag suspension system give the operator a smooth ride. The main tank is strategically located between the front and rear axles, in conjunction with the boom, cabin and engine drive line positioning delivers a sprayer with an almost perfect 50/50 weight split. This reduces ground compaction by evenly distributing the weight across all four tyres. The result, perfect balance.

36 to 48m TriTech V boom

Today’s sprayers are full of bells and whistles which makes spraying a whole lot easier, comfortable and efficient, but it’s easy to forget what the end goal is. Precise chemical application.

Boom control can be the difference between a good spray result, and no result at all. Goldacres understand this and it is why all our sprayer designs are centred around the boom first and foremost.

Why do Goldacres booms ride so well?

Goldacres pioneered the use of lightweight aluminium in the outer boom wings over two decades ago. The philosophy was, and still is today that mass on a boom is fine so long as it is as close to the centre as possible. Reduced mass on the boom extremities reduces boom forces in both yaw and roll. This combined with the unique boom suspension results in a very stable boom ride, regardless of the terrain.

TriTech booms are contour following, meaning that the boom level will be referenced to the sprayer chassis and not purely on gravity such as a pendulum boom. This allows the sprayer to transverse the sides of hills and contours whilst keeping the boom level to the ground at all times. This results in placing the nozzle at the optimum height above the target.

TriTech V Series boom range is designed for operators who demand the utmost performance, reliability and control. Time and time again the TriTech boom has been named No.1 for boom stability*, which at the end of the day, achieves a superior spray result.

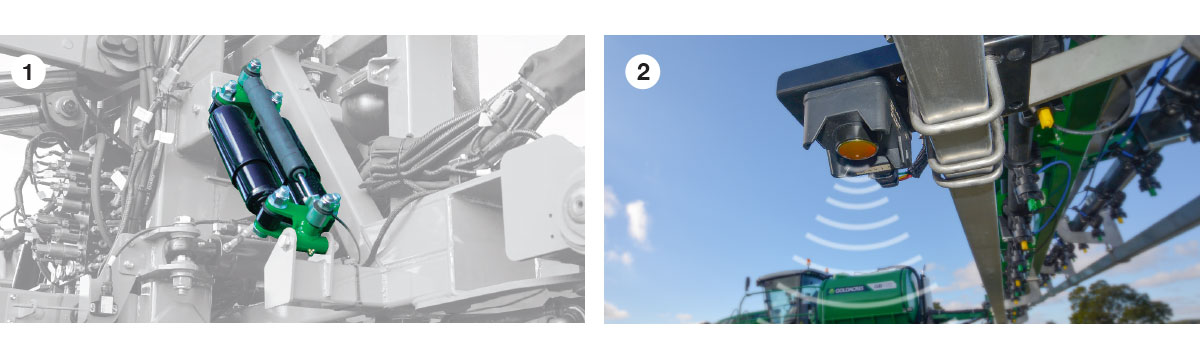

1 Outer boom wings / breakaway

- Outer boom wings are aluminium trussed

construction for exceptional strength,

chemical resistance and lightweight. - Boom breakaways feature a three

dimensional break forward, back and up

mechanism.

2 Inner boom wings

- Inner boom wings are manufactured using

RHS trussing with nozzle bodies protected

behind the boom structure. - Hydraulic Bi-fold is built into the design.

3 Boom fold

- Boom fold functions are operated via rocker

switches / outer wing latching secures the

boom for transport.

4 Boom Centre

- Boom centre section incorporates the proven

TriTech suspension to dampen the forces of

Yaw, Roll and Pitch. - XRT radar boom height control system

is fitted standard.

5 Boom Plumbing

- ¾” boom plumbing mounted behind boom

structure, infinite nozzle spacing.

Productivity and flexibility when you need it, 48m, 36m or 20m spray widths at the push of a button.

The 48m TriTech V boom is constructed as a tri-folding design. This method of boom construction dramatically reduces the overall folded length of the sprayer compared to two fold booms making storage and transporting much easier. Clever packaging of the folded sections results in a relatively narrow transport width of just 4.3m without impeding on operator entrance to the cabin. The tri-folding construction also allows for multiple spray widths to be achieved. The boom can be operated in either 48m, 36m or 20m widths.

1 20m spray width

- Mid and outer section folded back.

2 36m spray width

- Outer section fold back.

3 48m spray width

- Fully open.

A 48m wide boom compared to a 36m can potentially achieve a 33% increase in productivity (depending on application rate).

- 36m boom at 25km/hr = 90ha/hr.

- 48m boom at 25km/hr = 120ha/hr.

1 Centre Section

- Provides control for the boom. Featuring

TriTech suspension, the centre section uses

hydraulics to control boom yaw and

dampeners for the roll. Pitch of the boom is

controlled via hydraulic accumulators fitted to

the paralift arms.

2 Inner Wings

- Steel RHS truss structure provides strength

and flexibility to support the mid and outer

wings. - Accumulation is built into the fold cylinders

to provide cushioning when accelerating

or decelerating, reducing forces on the entire

boom. - A latching mechanism supports the mid &

outer boom wings to the inner, while in the

20m working and transport position.

3 Mid & Outer Wings

- Full truss aluminium construction to provides

strength and lightweight. - Three dimensional breakaways and fitted to

the end three meter boom section.

4 Plumbing

- 1” boom plumbing is fitted for both higher

application rates but to also reduce pressure

drop along the length of the boom.

5 Height Control

- XRT radar boom height control is fitted as

standard –

AutoBoom XRT radar sensor technology uses simultaneous ground and canopy detection to maintain optimal spray height for maximum product efficacy.

Pressure-based control allows for smooth movement and quicker reaction time while centre rack stability technology with variable dampers gives the system complete boom control.

1 Centre section

- The variable rate dampeners are used to

stiffen the centre section roll action when

wing tilts are operated. This allows much

quicker reactions to occur without effecting

the overall stability of the opposing boom

wing.

2 Height sensors

- The height sensors use radar based distance

technology. The radar sensors enable a

larger height measurement range, can detect

both ground and crop canopy and are less

effected by spray drift, dust and mud. - The system uses additional sensors

to monitor the sprayer chassis rate of roll,

the boom centre position relative to the

chassis as well as boom wing tilt angle.

These extra sensors allow the computer to

predict how the boom will react well before

the radar sensors even see the change in

boom height. The end result is a more stable

boom in uneven terrain.

A boom which bounces, sways or yaws deposits chemical unevenly on the target. This can result in weed escapes and may even contribute to resistant weeds.

The Goldacres TriTech suspension system has been developed to provide you with the best boom ride possible and assist in an accurate application.

Working in conjunction with the chassis airbags the boom features three way suspension that works to reduce boom pitch, roll and yaw – the three enemies of accurate application. Hydraulic cylinders and accumulators work together to provide the best boom ride possible.

The TriTech suspension system has contributed to Goldacres consistently having the best boom ride

in the spraying industry.

Every agricultural operation is looking to improve its efficiency wherever possible. Correct batching and mixing of product to the label is the start of any spraying task. The ultimate in mixing and transferring chemicals is the 800L Goldacres BatchMate*.

This standalone batching system allows chemicals to be pre-mixed easily, safely and quickly ready for transfer into the sprayer via the dirty 3” connection point on the sprayer. The BatchMate features its own high flow engine driven centrifugal pump so there is no need to leave the sprayer engine running whilst filling, substantially reducing engine hours over the duration of the annual spraying program. All the controls are well labelled and laid out to make chemical transfer safe and intuitive. For more details on the BatchMate refer to your Goldacres dealer.

- 800L product tank.

- Venturi chemical induction probe.

- Drum buster bag splitter.

- 23L handwash tank with soap dispenser.

- Drum / Jug rinse nozzle with stainless basket.

- 3” transfer outlet.

- Honda GX200 petrol engine and 3” high volume centrifugal poly pump.

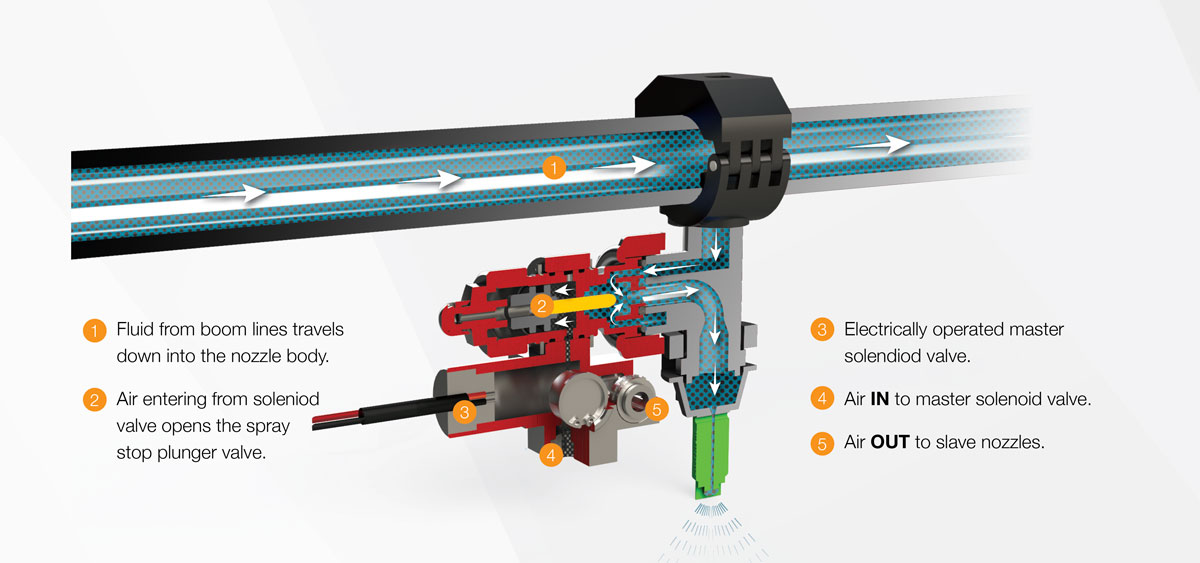

RapidFire is instant boom nozzle on / off capability with 16 section control. Quick line priming and flushing of spray lines with RapidFlow boom recirculation.

RapidFire

Goldacres pioneered RapidFire technology on Australian built sprayers in 2006. At the time the new technology vastly improved section switching times by replacing traditional motorised boom section valves with air controlled switching right at the nozzle. RapidFire DM (Direct Master) further improves on this by moving the electric over air solenoid from a bank in the centre of the sprayer to the first nozzle of each section. This results in a significant reduction in air hose required and also evens up the switching time across all sections of the boom.

The boom is configured in 16 sections to improve spray resolution when using an auto section controller for odd shaped paddocks. Goldacres have determined that 16 sections provides the perfect balance between spray overlapping and complexity.

RapidFlow (Boom Recirculation)

RapidFlow allows the sprayer boom lines to be fully primed without spraying a single drop. This reduces wastage at the start of a tank load or when switching chemicals. RapidFlow can also be used to thoroughly flush out the boom lines without the need to physically spray on the ground.

Nozzle technology has advanced in leaps and bounds over the years and a strong emphasis on drift control has influenced many nozzle designs

3TS

The spray nozzles operating pressure range and size determine the application rate and speed band at which the driver must adhere to. This band is usually quite narrow. Goldacres offer a 3 tier system (3TS) which effectively gives the driver a much wider operating band whilst still maintaining optimum droplet size.

Think of 3TS as a three step gearbox. Each

nozzle type has an operating pressure band for a given droplet size. As the first nozzle reaches the top of the pressure band it switches off and the next larger size nozzle switches on. When that nozzle reaches the top of that pressure band the first nozzle will switch on again, effectively giving three operating bands.

The table below shows the pressure variations of two common nozzles, 015 & 02 operating at 70 l/ha through their respective pressure ranges from 7 km/h through to 27 km/h.

3TS Pro – the ultimate control and flexibility without leaving the cab.

The 3TS Pro is essentially our 3TS system with an added nozzle to give a wider range of spray rates without manually changing jets.

If you are constantly changing rates but want to keep your speed consistent, the 3TS Pro is for you.

For example you may want to apply 70 l/ha with your combination of 015 & 02 nozzles to give the overall capacity of an 035 nozzle (as per 3TS chart shown), then increase your rate in certain parts of the crop, other paddocks or even in the application of fertilisers.

In most cases you would need to slow down to increase the rate as you would previously exceed the nozzle pressure range. With the additional nozzle the 3TS Pro will automatically select the best nozzle combinations for your speed and rate while maintaining the working pressure range of the nozzles.

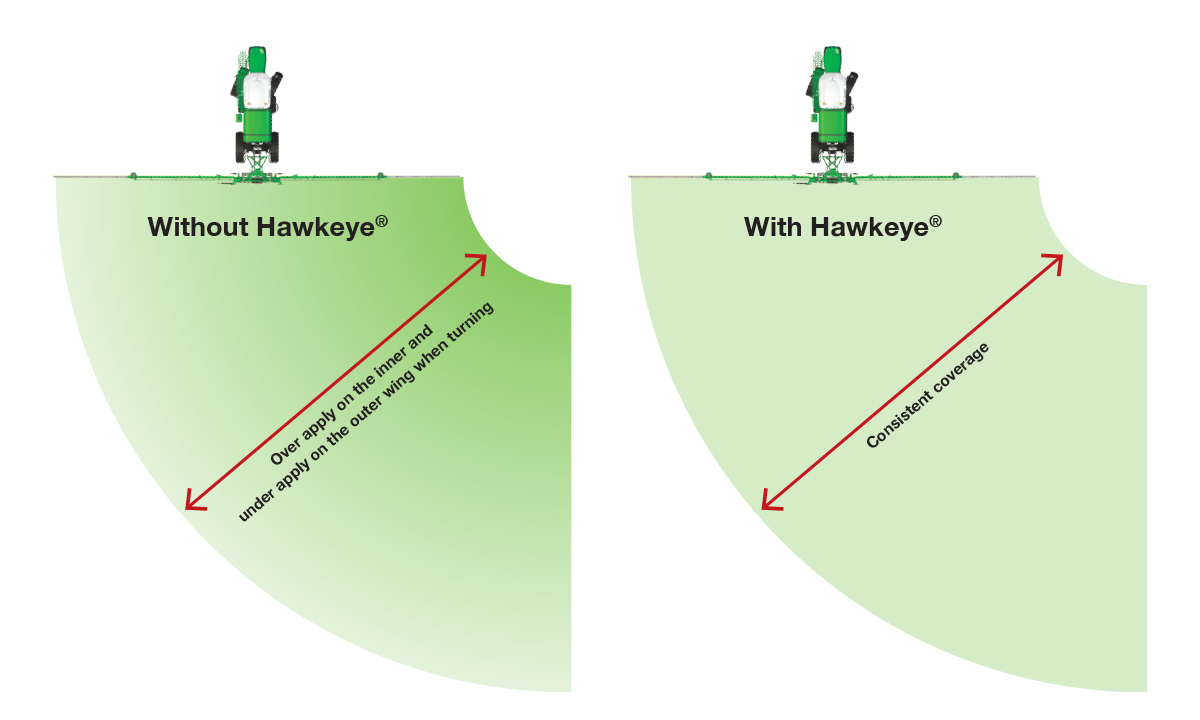

Pulse Width Modulated (PWM) technology is now available as an option for your Goldacres sprayer.

PWM technology uses a small electrically operated solenoid mounted to the nozzle body to control the flow rate delivered to each nozzle. The system rapidly pulses the nozzle on and off at rates of 10hz (10 times per second) whilst also adjusting the amount of time the nozzle is opened and closed (this is called the duty cycle). The spray line is set to maintain a constant liquid pressure, whilst the computer adjusts the duty cycle to vary the application rate. The system allows the selected nozzle to operate at a target droplet size independent of the forward speed (within the system and nozzle capacity)

Using the PWM technology also provides a method of providing turn compensation. When making a turn the inner wing tip speed slows and the outer wing tip speeds up, which in turn over and under applies chemical to the target. As each nozzle is controlled independently it is possible to adjust the duty cycle to either decrease or increase the application rate across the entire width of the boom.

Features:

- Nozzle by nozzle turn compensation.

- 16 virtual sections or the option to have individual nozzle sections.

- Fully integrated into the G-Hub system as well as ISO BUS compatible.

- Available in either 250mm or 500mm spacing.

1 Without Hawkeye®

- Over apply on the inner and under apply on

the outer wing when turning.

2 With Hawkeye®

- Consistent coverage when turning. Note:

within nozzle parameters.

Whether you’re spraying in the field or driving down the road, uninterrupted vision around the sprayer is essential for the safety of you and others

Features like the flat folding boom wings so the operator’s line of sight is uninterrupted. Electrically adjustable side mirrors provide a clear view of the road behind. 360º rotation windscreen wiper blade for maximum cleaning area of the front window. Hydraulically adjustable LHS boom rest provides the operator with easy access to the cabin in the wide position yet brings the overall transport width down for road transport*, eliminating the need for an escort vehicle. Twin circuit, 4 wheel internal multi-disc brakes fitted as standard. LED daytime running lamps, turn indicators, high / low beam projector style halogen head lights and twin rotating warning beacons round out the package. The Super Cruiser really is one for the road.

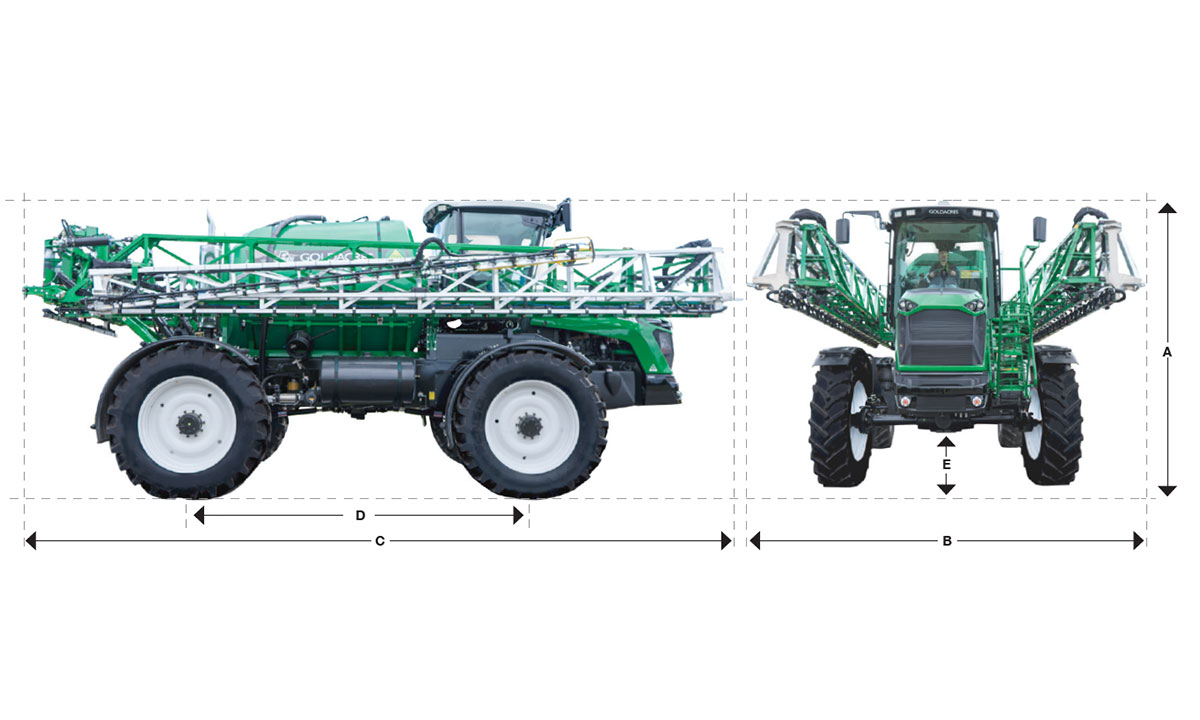

| Dimensions | A (m) | B (m) | C (m) | D (m) | E (m) |

|---|---|---|---|---|---|

| 36m Boom | 4.3 | 3.6 | 9.85 | 4.45 | .94 |

| 42m Boom | 4.3 | 3.6 | 10.4 | 4.45 | .94 |

| 48m Boom | 4.3 | 4.2 | 9.35 | 4.45 |

*3.5m when 480/80R46 tyres fitted at standard wheel track 2970mm. ^Not on 48m boom.

| Feature | Description | G8 |

|---|---|---|

| Engine | Cummins QSB 6.7L, 6 cylinder, Tier 3 emission. 194kw (260hp), 987N.m (728lb-ft) | Standard |

| Vertically stacked combi cooler package. Fuel, transmission, water jacket, charge air, and air conditioning | Standard | |

| Hydraulic-driven cooling fan | Standard | |

| 440L fuel tank featuring dual fillers | Standard | |

| Transmission | Allison 3000 series automatic. Push-button selector, lock-up torque converter, 6 forward and 1 reverse | Standard |

| Drive system | Full-time 4WD | Standard |

| Centre diff lock | Standard | |

| Rear diff lock | Standard | |

| Steering | ||

| 2 wheel front steering system | Standard | |

| Steering radius (machine centre point) | 11m | |

| Hydraulics | 100L plastic reservoir with level and temperature gauge (visible from driver’s seat) | Standard |

| 63cc variable displacement hydraulic piston pump | Standard | |

| 22cc gear pump (Fan and brake system) | Standard | |

| 32cc gear pump for spray pump system | Standard | |

| Tank mounted return filter | Standard | |

| Oil Cooler | Standard | |

| Electrical | 12v – 160amp electrical capacity | Standard |

| Dual batteries with master isolator | Standard | |

| Fully sealed connectors with color coded wires used throughout the wiring harness | Standard | |

| 4 x LED front mounted and 2 x LED rear mounted roof driving lights | Standard | |

| 3 x LED service lights | Standard | |

| LED light bar for lower bonnet (18x10W CREE) | Option | |

| LED light bar for upper cabin (12x10W CREE) | Option | |

| Braking | Full hydraulic twin circuit system with accumulator backup | Standard |

| 4x wet brakes inside axle housing | Standard | |

| Electric over hydraulic operated park brake on rear axle | Standard | |

| Chassis | Fully welded, wide, semi truss, rigid mild steel | Standard |

| 200 x 100 x 9mm main rails | Standard | |

| Suspension | 5 link torque rods with rear sway bar. 4 x rolling lobe air springs with ride height levelling. Shock absorbers on all corners, front feature double knuckle for extreme axle articulation | Standard |

| Paint | Grit blasted steel work followed by high build primer. All unwelded sections seam sealed | Standard |

| Wet top coat paint system with high temperature baked finish | Standard | |

| Wheels and Axles | 520 R46/85 tyres | Standard |

| 3m axle track | Standard | |

| 4 x full length axle mounted polyethylene mudguards | Standard | |

| Cabin | Business class styled cabin with suspension | Standard |

| Dual tilt and telescopic steering column | Standard | |

| Air suspension seat with seat belt. Fully adjustable | Standard | |

| Training seat with seat belt | Standard | |

| Accessory mounting rail on RHS | Standard | |

| Window tint for all 4 sides | Option | |

| Refrigerator module for storage compartment | Option | |

| Under training seat | Option | |

| Carbon filtration with positive cab pressurisation | Standard | |

| Bluetooth equipped radio and UHF with high | Standard | |

| gain antennas | Standard | |

| LHS access platform with auto folding ladder. Hydraulically adjustable width LHS boom rest for ease of access and convenient road transport | Standard | |

| Boom | TriTech flat folding boom. Mild steel inner wings with aluminium outer wings and breakaway | Standard |

| Available in the following widths. 36, 42 & 48m. All booms plumbed in 16 sections | Standard | |

| RapidFire single line in 500mm spacing | Standard | |

| RapidFlow boom recirculation | Standard | |

| 3 tier system (3TS) | Option | |

| 3 tier system PRO (3TS PRO) | Option | |

| Raven Hawkeye (PWM with turn compensation) | Option | |

| Weedetect – Green on Green / Green on Brown weed detection system | Option | |

| Trijet nozzle bodies | Option | |

| Cross fire 3TS (3TS capability with nozzles staggered every 250mm) | Option | |

| Extra boom sections available | Option | |

| Custom nozzle spacing and configurations on request | Option | |

| Hydraulic wing tilt | Standard | |

| Hydraulic bi-fold | Standard | |

| Hydraulic yaw system | Standard | |

| 5 sensor active wing roll boom height leveller now | Standard | |

| Remote fence line jets | Option | |

| Spray control system | ISO BUS control system (no VT supplied) | Standard |

| Solution tanks | UV stable Polyethylene heavy walled tank. Supported in a steel cradle | Standard |

| Main tank – 8000L | Standard | |

| Rinse tank 500L side mount | Standard | |

| Dry sight tube mounted on LHS | Standard | |

| Spray Pump | High Flow centrigual pump | Standard |

| 260 l/min, oil backed 6 diaphragm positive displacement. RPM readout | Standard | |

| Suction filter plus twin pressure filters | Standard | |

| Chemical handling and transfer | ||

| Chemical suction probe | Standard | |

| 60L induction hopper | Standard | |

| Micromatic rinse socket and coupler | Option | |

| Pneumatic chemical transfer pump 40 l/min capacity | Standard | |

| 3″ integrated water transfer pump | Standard | |

| 3″ separate front fill | Option | |

| 3″ separate side fill | Standard | |

| Service / Maintenance | Remote grease nipple bank | Standard |

| Auto grease system | Option | |

| Weight | Weights are approx. and depend on options fitted | |

| Tare weight* (kg) | 12,075kg | |

| Gross weight* (kg) | 20,275kg |

- G8 / G10s Super Cruiser

- 2022

- R3

- GA8700542-R3

- 4mb

- View Online

- Download

- G8 Super Cruiser - 48m Boom

Reviews

There are no reviews yet.